Can You Use a Drill as an Impact Driver? Discover The Truth Here!

Have you ever found yourself in the middle of a DIY project, wishing you had the right tool for the job? If you have a drill lying around, you might be wondering if it can double as an impact driver. The short answer is yes, but before you rush off to try it out, there are a few things you should know. In this blog post, we’ll take a closer look at what exactly an impact driver does, how it differs from a drill, and whether or not you can use a drill as an impact driver.

So sit back, grab your trusty drill, and let’s dive into the world of power tools.

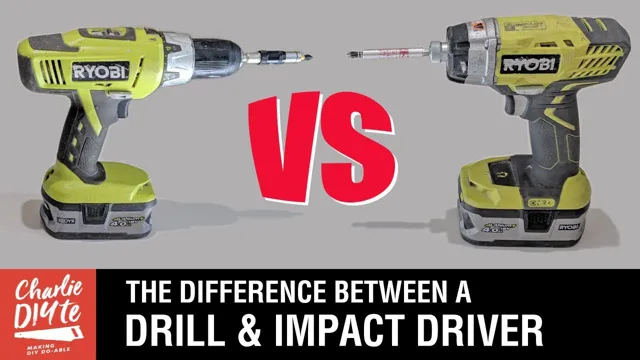

Understanding the difference between a drill and an impact driver

Many people wonder if they can use a drill as an impact driver, and the answer is no. While both tools may look similar, they have different functions. A drill is used primarily for drilling holes and driving screws into wood or metal, while an impact driver is designed to drive long screws and bolts with great speed and force.

An impact driver has more torque and can withstand the high torque needed for tasks such as driving lag bolts, while a drill lacks this capability. Using a drill as an impact driver may cause damage to both the tool and the screws being driven, as it cannot deliver the required force and torque. It’s essential to choose the right tool for the job to ensure the job is completed correctly and safely.

So, the next time you’re faced with a project that requires the use of an impact driver, remember to choose the right tool for the task at hand.

The primary function of a drill

A drill is a versatile power tool that is used to make holes in various materials, including wood, metal, and plastic. The primary function of a drill is to create holes of different sizes and shapes, depending on the type of bit used. The tool can also be used to drive screws and bolts into different surfaces.

In contrast, an impact driver serves a specific purpose of driving screws and bolts with greater force and speed than a drill. Impact drivers are more powerful than drills and can also be used to loosen stuck screws and nuts. Understanding the difference between the two tools is essential, as it will help you choose the right tool for the job.

Drills are perfect for drilling holes in various materials, while impact drivers are suitable for driving fasteners into tough materials. Therefore, it’s crucial to evaluate your project’s requirements before deciding on which tool to use.

The primary function of an impact driver

Impact driver An impact driver is a powerful tool that is designed to make tough jobs easier. Many people confuse impact drivers with drills, but the truth is they are quite different. While a drill rotates the bit to create a hole or drive a screw, an impact driver combines rotation with a hammering action to apply more torque to the screw.

This means that impact drivers are incredibly efficient at driving long screws and larger fasteners through even the toughest materials like hardwood or metal. It’s important to understand that impact drivers are not designed for drilling. Using them to drill holes can cause damage to the tool, which would require costly repairs.

Instead, they are best used for heavy-duty tasks like decking, framing, or fixing automotive parts. One of the best things about impact drivers is that they are incredibly versatile. They come with a variety of attachments that can be easily swapped out, making them suitable for different types of jobs.

They are also very easy to use, requiring minimal effort to drive even the largest of screws. In summary, the primary function of an impact driver is to drive screws and fasteners through tough materials quickly and efficiently. It’s important to understand the difference between a drill and an impact driver to avoid causing damage to your equipment.

Impact drivers are best used for heavy-duty jobs, making them an essential tool for any DIY enthusiast or professional tradesperson.

Drill vs impact driver: What are the main differences?

When it comes to DIY projects, having the right tools is essential. Two popular tools that often get confused are drills and impact drivers. While both can drill holes and drive screws, they serve different purposes.

An impact driver is perfect for tasks that require more power and torque, such as driving long screws into dense materials like hardwood or decking. On the other hand, a drill is better suited for tasks that involve drilling holes in wood, metal, or plastic and driving shorter screws into softer materials. That being said, you cannot use a drill as an impact driver because it lacks the necessary power to drive long screws into dense materials.

So, it’s important to have both tools in your arsenal to tackle any DIY project with ease.

Torque and speed

When it comes to power tools, two of the most commonly used devices are the drill and the impact driver. While they may look alike, there are some significant differences between these two devices. One of the main differences is in how they generate power.

Drills rely on torque, while impact drivers use both torque and speed to create a powerful impact force. The torque provides the rotational force needed to drive screws and drill holes, while the speed allows the impact driver to generate repeated blows that can break loose stubborn bolts or screws. Another key difference is the application.

Drills are great for drilling holes in wood, metal, and drywall, as well as for driving screws into these materials. However, when it comes to tougher applications, such as working with dense hardwoods, masonry, or metal, an impact driver is the way to go. These tools are specifically designed for tasks that require high-torque, high-speed applications and can easily power through even the most challenging materials.

In conclusion, both drills and impact drivers have their strengths and weaknesses. It’s important to know which tool to use in which situation. For general DIY projects and light-duty work, a drill is sufficient.

But if you need to tackle heavy-duty construction projects, an impact driver will be your best friend. Understanding these differences will help you make the right choice for your projects and ensure the best results.

Anvil mechanism

When it comes to choosing between a drill and an impact driver, one of the main differences is the mechanism used to generate torque. Drills use a simple motor to spin the chuck, which then rotates the drill bit or driver. Impact drivers, on the other hand, use an anvil mechanism to deliver high-torque, rapid bursts of force to the bit or driver.

This makes them ideal for tasks that require driving screws or fasteners into tough materials like metal or hardwood. So why choose a drill over an impact driver? While drills may have less torque overall, they are better suited for drilling holes and performing tasks that require precision and control. Impact drivers, on the other hand, are better suited for heavy-duty tasks where speed and power are essential.

Ultimately, the choice between a drill and an impact driver comes down to the types of tasks you will be performing and your personal preferences.

Size and weight

When comparing a drill and an impact driver, one of the key differences is their size and weight. Typically, impact drivers are smaller and lighter than drills. This makes them ideal for tasks requiring higher precision or when working in tight spaces where maneuverability is crucial.

On the other hand, drills are bulkier and heavier, which can make them more challenging to use for extended periods. However, drills have more power and can handle a wider range of materials, making them better suited for heavy-duty tasks. When selecting between a drill and impact driver, it’s crucial to consider the size and weight based on the type of work you will be doing.

If you require higher accuracy and maneuverability, an impact driver may be the better option. However, if you need more power and versatility, a drill may be the way to go.

Using a drill as an impact driver

Many people often wonder if they can use a drill as an impact driver to save money and space in their toolbox. While both tools have the same basic function of drilling holes, they perform differently when it comes to the task of driving screws. A drill rotates in a steady clockwise motion and is great for creating deep, accurate holes.

An impact driver, on the other hand, produces strong bursts of torque and trudges more quickly through screw driving tasks. However, in a pinch, a drill with a hex shank chuck can be used to perform some light impact driving tasks. It’s important to keep in mind that using a drill as an impact driver can wear down the motor more quickly and damage the chuck.

Overall, if you want to perform a lot of heavy-duty screw driving tasks, it’s recommended to invest in an impact driver designed specifically for that task.

Benefits and drawbacks of using a drill as an impact driver

Using a drill as an impact driver has its benefits and drawbacks, and it’s important to know what they are before deciding whether to use a drill or an impact driver for your project. One of the major benefits of using a drill as an impact driver is that it’s a versatile tool that can be used for drilling and driving screws. This saves you the money and space of having to purchase two separate tools.

However, when it comes to removing screws, a drill may not have the same amount of torque as an impact driver. Additionally, an impact driver is designed specifically for driving screws, so it’s often faster and more efficient than a drill. Another downside of using a drill as an impact driver is that it may prematurely wear down the clutch or chuck, resulting in the need for more frequent repairs or replacements.

Overall, if you’re working on a project that requires a lot of screw driving, it’s worth investing in an impact driver. However, if you only need to use a drill occasionally for drilling and driving screws, a drill may suffice.

Steps to use a drill as an impact driver

If you’re in a pinch and need to use a drill as an impact driver, it is possible with some steps to follow. Firstly, ensure the drill is compatible with impact driver bits, which are designed for high torque and impact resistance compared to regular bits. Then, adjust the clutch to the highest setting or switch to drill mode.

Next, insert the impact driver bit and tighten it securely. Remember to wear eye protection and grip the drill tightly to control the impact, as it can be stronger than a regular impact driver. With these steps, you can use a drill as an impact driver, but keep in mind that it may not be as effective or long-lasting as an actual impact driver.

So, use this as a temporary solution rather than a long-term replacement for an impact driver.

Conclusion

In conclusion, while a drill and an impact driver may seem interchangeable, they each serve distinct purposes. While a drill is ideal for handling light to moderate tasks, an impact driver is the heavy-duty solution for driving screws, nuts, and bolts. So, can you use a drill as an impact driver? Sure, you can also use a butter knife as a screwdriver, but you wouldn’t want to try building a house with it.

Invest in an impact driver for those tough jobs, and you’ll save yourself time, energy, and any potential tool mishaps.”

FAQs

What is the difference between a drill and an impact driver?

A drill is designed primarily for drilling holes, while an impact driver is used for driving screws or bolts with greater speed, torque, and accuracy.

Can you use an impact driver for drilling holes?

While an impact driver can be used for drilling holes, it is not designed for this purpose and may not work as well as a drill.

What kind of jobs are best suited for an impact driver?

Impact drivers are ideal for jobs that require driving large or long screws, fastening bolts, or working with dense materials like hardwood or metal.

Can you use a drill bit on an impact driver?

Yes, impact drivers can accept standard drill bits, although you may need to use a hex shank adapter to fit the bit into the driver.

Do you need special bits for an impact driver?

While standard bits can work with an impact driver, it is recommended to use impact-rated bits, which are designed to withstand the high torque and force generated by the driver.

How do you adjust the torque on an impact driver?

Most impact drivers have adjustable torque settings, usually represented by numbers on the driver. Lower numbers correspond to lower torque, while higher numbers correspond to higher torque.

Can an impact driver replace a drill in my toolbox?

While an impact driver can perform some of the same functions as a drill, it is not designed to replace a drill entirely. For most jobs, it is recommended to have both tools in your toolbox.