Can An Impact Driver Use Drill Bits? Discover The Possibilities!

Have you ever wondered whether you can use drill bits with an impact driver? If you’re someone who loves DIY projects, or someone who likes to get their hands dirty with house repairs, then this question might have crossed your mind. It’s not surprising that some people are confused about whether or not you can use drill bits with an impact driver. After all, they seem so similar, don’t they? But the truth is, they are quite different tools with unique functionalities.

In this post, we’ll take a closer look at whether or not you can use drill bits with an impact driver and what to keep in mind when doing so. Let’s dive in!

Understanding Impact Drivers

If you’re wondering whether an impact driver can use drill bits, the answer is yes – but with a catch. Impact drivers are different from regular drills in that they use rotational force combined with concussive blows to drive screws and bolts into tough materials like wood and metal. While they can technically use drill bits, it’s not recommended to use them for drilling purposes as the impact mechanism can damage the bits and reduce their lifespan.

It’s best to reserve your impact driver for driving screws and bolts, and use a regular drill for drilling applications. Keep in mind that impact drivers are designed to provide extra torque and power, making them a great choice for heavy-duty tasks, but they may not be the best choice for more delicate projects. So, can an impact driver use drill bits? Yes, but it’s not advisable.

How Do Impact Drivers Work?

Impact Drivers Impact drivers are powerful, cordless tools used for driving screws and bolts with ease. They work by using a combination of rotational force and concussive blows to power through tough materials such as concrete, masonry, and metal. The rotational force comes from the motor, while the concussive blows come from a mechanism inside the tool that hammers the drill bit forward at a rapid rate.

These blows create a burst of high-torque power that makes it much easier to drive the screw or bolt into the material. This unique mechanism allows impact drivers to be incredibly fast and efficient when compared to other drills. Their design also reduces the amount of strain on the user when using the tool for extended periods of time.

Impact drivers are highly versatile and are a must-have tool for DIY enthusiasts and professionals alike.

Why Use an Impact Driver?

Impact drivers are a type of power tool that have gained popularity among both professionals and DIY enthusiasts in recent years. They are designed to deliver more torque and power than traditional cordless drills, making them perfect for heavier-duty jobs such as driving long screws or bolts. What sets impact drivers apart from other power tools is their unique mechanism, which delivers a series of quick bursts of power or impacts to the screw or bolt being driven.

This allows the tool to power through tough materials with less effort and in less time than other tools. Think of it like a punching bag – each impact helps the tool drive the screw or bolt deeper into the material until it is completely set. If you’re tackling a big project that requires a lot of screw-driving or drilling, an impact driver could be just the tool you need to get the job done quickly and efficiently.

Compatibility of Drill Bits and Drivers

If you’re looking for a quick answer, yes, an impact driver can use drill bits. However, it’s important to note that not all drill bits are created equal, and not all drivers are designed to work with every type of bit. Impact drivers, for example, use a different mechanism than regular drills and require specialized bits that are able to withstand the high torque that impact drivers generate.

While some drill bits can be used with an impact driver, it’s best to use bits that are specifically designed for this type of tool. This will ensure that you get the best performance and the greatest longevity out of both your bits and your driver. So if you’re planning on using an impact driver for your next project, make sure to invest in bits that are compatible and up to the task.

Type of Drill Bits That Can Be Used with an Impact Driver

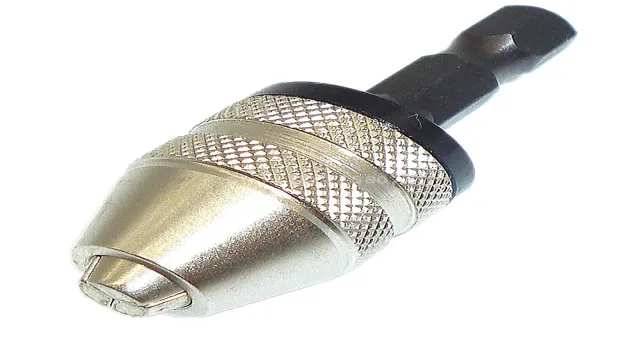

Impact drivers are becoming a popular choice for DIY enthusiasts and professionals alike due to their high power and efficiency when it comes to drilling through tough materials. However, it can be confusing to know which type of drill bits are compatible with an impact driver. Typically, you should only use hex shank bits with an impact driver, as they are designed to fit snugly into the driver’s chuck for maximum grip and stability.

Other types of drill bits, such as those with round or flat shanks, may not fit properly and can cause slippage and damage to both the bit and the driver. It’s also important to consider the material you’ll be drilling into when choosing the right bit for your impact driver, as some materials require specialized bits such as masonry, metal, or wood bits. By choosing the right type of bit for your impact driver, you’ll not only ensure successful drilling but also prolong the lifespan of both your tools.

Drill Bit Size Compatibility with Impact Drivers

When it comes to using an impact driver with drill bits, compatibility is essential for efficient and safe operation. Most impact drivers have a 1/4-inch hexagonal chuck that can fit with a range of hexagon-shaped drill bits. However, not all drill bits are compatible with impact drivers.

For example, standard twist drill bits are not recommended for use with an impact driver due to their design, which makes them vulnerable to cracking and breaking under the high forces generated by the impact driver. Instead, it is best to use impact-rated drill bits that can withstand the high torque and vibrations produced by the impact driver. These specially designed drill bits have a shorter length for increased durability and are made from materials that are more impact-resistant.

It is essential to ensure that the drill bits are compatible with the impact driver before usage, as the wrong type of drill bit can cause damage to both the drill bit and the tool itself. By using the right drill bit, you can work more efficiently and get the job done with ease.

Considerations When Using Drill Bits with Impact Drivers

When using an impact driver, it is crucial to ensure that the drill bits used are compatible with the driver. Not all drill bits are created equal, and certain types may not be suitable for use with impact drivers. Using the wrong type of drill bit can lead to damage or injury.

Impact drivers are designed to impart high levels of torque quickly, making them a versatile tool for heavy-duty tasks. However, standard drill bits may not be able to withstand the rigors of impact driving. Therefore, it is essential to use impact-rated drill bits are specifically designed for use with impact drivers.

By doing so, you can ensure that your tools operate at maximum efficiency and safety is maintained. Using non-compatible drill bits for impact drivers can be dangerous and may cause harm to both the operator and the equipment. Hence, always choose the correct type of drill bit for your impact driver to get the job done safely and effectively.

Impact Driver Accessories

Yes, an impact driver can use drill bits. However, it is important to use drill bits that are specifically designed for use with impact drivers, as regular drill bits may not withstand the high torque and impacts generated by the tool. Impact driver drill bits are made from high-quality materials such as cobalt and titanium, which provide greater durability and reduce the likelihood of breakage.

In addition to drill bits, there are other accessories you can use with your impact driver to increase its versatility and functionality. For example, you can attach a socket adapter to your impact driver to use it for tightening or loosening nuts and bolts. You can also use a magnetic bit holder to keep your drill bits in place while you work.

With the right accessories, your impact driver can become an incredibly versatile tool that can handle a wide variety of tasks around your home or workshop. So, if you have an impact driver, be sure to invest in the right accessories to make the most of its capabilities.

Impact Rated Driver Bits

Impact rated driver bits are a must-have accessory for any tradesperson or DIY enthusiast who uses an impact driver. These bits are specifically designed to withstand the high torque and fast rotational speeds produced by impact drivers, making them more durable and long-lasting than standard driver bits. With their unique design, impact rated driver bits provide a tight and secure fit inside the fastener head, minimizing the risk of stripping or camming out.

This ensures that you can work efficiently without the frustration and downtime of having to replace worn-out driver bits. Impact driver accessories like impact rated driver bits are essential for anyone who wants to get the most out of their power tools. So, the next time you’re considering a project that requires an impact driver, make sure you have a set of impact rated driver bits on hand and experience the difference for yourself.

Impact Rated Socket Adapters

Impact rated socket adapters are essential accessories for those who use impact drivers regularly. These adapters are designed to fit onto the driver, allowing you to use different types of sockets efficiently. They have been manufactured using superior quality materials that can withstand the high torque and pressure of impact wrenches.

The adapter’s ball-bearing mechanism ensures maximum grip and engagement with the socket, preventing it from slipping off during high-torque applications. Impact rated socket adapters come in various sizes that can fit different sockets and hex bits, making them versatile and convenient. By using them, you’ll get the most out of your impact driver and make your work easier and faster.

Investing in high-quality impact rated socket adapters will save you time and effort in the long run and will help you get the job done correctly and efficiently.

When to Use a Drill Instead

Many people may wonder if they can use drill bits with their impact driver, but the answer is not always straightforward. While an impact driver can accommodate drill bits, it is not the ideal tool for drilling holes as the force it delivers is mainly rotational, making it more suited for driving screws and bolts. A drill, on the other hand, is designed specifically for drilling holes and can apply force in a linear motion, making it the better choice for such tasks.

So, when should you use a drill instead of an impact driver? If you need to make precise holes, drill through tougher materials like concrete or metal, or work with larger bits, a drill is the way to go. While impact drivers can be versatile tools, it is important to use the appropriate tool for the job to ensure better results and prevent damage to your equipment.

Materials That May Require a Drill Instead of an Impact Driver

When it comes to DIY projects, having the right tools for the job is crucial. While an impact driver may be a versatile tool, there are times when a drill is a better option. If you’re working with materials like tile or glass, for example, using a drill is a more appropriate choice.

Drills provide greater precision and control, allowing you to make small, controlled holes without shattering the material. Additionally, working with hard materials like concrete or steel may require a specialized drill bit and a more powerful tool to get the job done. So, when deciding whether to use a drill or impact driver, consider the material you’re working with and what type of hole or fastener you need to create.

This will ensure you have the right tool for the job and a successful outcome.

Conclusion

In conclusion, while an impact driver may be able to use drill bits, it’s not necessarily the best or most efficient tool for the job. It’s like trying to eat soup with a fork – technically possible, but not ideal. So if you want to get the most out of your drill bits, it’s worth investing in a good quality drill that’s specifically designed for the task at hand.

Or as the famous saying goes, “use the right tool for the job, and you’ll save time and energy, without any unnecessary fuss or bother.”

FAQs

What is the main difference between an impact driver and a drill?

The main difference between an impact driver and a drill is that an impact driver delivers rotational force in short, quick bursts while a drill delivers a constant and steady force.

Can I use drill bits in an impact driver?

Yes, you can use drill bits in an impact driver as long as they have a hex shank that is compatible with the impact driver’s chuck.

What types of projects are best suited for an impact driver?

An impact driver is best suited for projects that require fastening screws with great speed and torque, such as deck building and woodworking.

How does an impact driver work differently than a regular drill?

An impact driver works differently than a regular drill by delivering rotational force in quick, powerful bursts that create more torque and speed than a regular drill.

What are the advantages of using an impact driver over a regular drill?

The advantages of using an impact driver over a regular drill include faster driving speeds, more torque, and less strain on the user’s wrist and arm due to the impact action of the driver.

How should I choose between an impact driver and a regular drill for my project?

If your project requires fastening screws quickly and with great torque, choose an impact driver. If your project requires drilling holes or requires precision, use a regular drill.

Do I need any special accessories for my impact driver?

Some useful accessories for your impact driver include hex shank drill bits, screwdriver bits of various sizes and types, and impact driver socket adapters for hex bolts.