How to Use Electronic Digital Caliper for Accurate Measurements: A Comprehensive Guide

Have you ever struggled with taking accurate measurements while working on a project? It can be frustrating to measure things with traditional tools such as a ruler or tape measure, especially when it comes to small and precise measurements. But don’t worry, there’s a solution to this problem – the electronic digital caliper! This handy tool can make taking measurements easy and accurate, no matter what the size or shape of the object you’re measuring. In this blog post, we’ll dive deep into how to use an electronic digital caliper effectively, covering all the necessary steps and tips.

So, let’s get started!

Introduction

If you’re looking for a precise way to measure small objects, then investing in an electronic digital caliper is an excellent option. But what are digital calipers, and how do you use them? Simply put, these calipers are advanced measuring tools used to measure the length, width, height, and depth of an object affected by multiple internal and external factors. They are precise, accurate, and highly portable, making them a go-to measurement tool for both professionals and hobbyists alike.

To use these digital calipers, you need to learn a few basic functions. Firstly, you have to set the unit of measurement, usually inches or millimeters, then use the jaws to take your measurement. Always ensure that the caliper surfaces make firm contact with the object you’re measuring for the most accurate results.

Additionally, digital calipers have a “zero” or “tare” button which lets you reset the measurements to zero for the next measurement. By following these steps and practicing with a few measurements, you’ll be well on your way to mastering the electronic digital caliper.

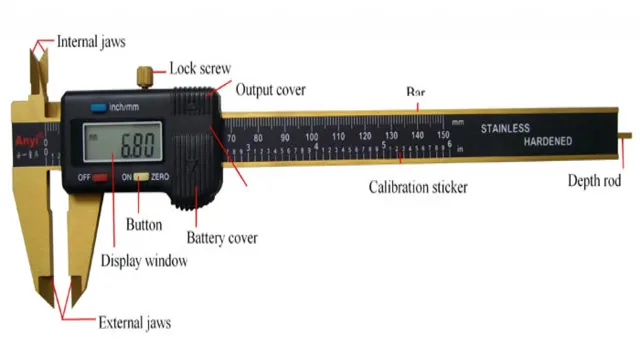

What is an Electronic Digital Caliper

An electronic digital caliper is a measurement tool used to take precise measurements of objects with extreme accuracy. It is an advanced version of the classic vernier caliper, and it uses an electronic sensor to provide digital readings on a screen. In simpler terms, it is a digital ruler that can measure length, width, and depth of an object within a fraction of a millimeter.

It is a highly popular and efficient tool used in various industries such as woodworking, metalworking, engineering, and the medical field. The main keyword, “electronic digital caliper,” refers to a tool that uses electronic sensors to provide accurate measurements. This provides a high degree of reliability and accuracy in measuring objects.

Why use an Electronic Digital Caliper

Electronic Digital Caliper Introduction: An electronic digital caliper is an essential tool for precise and accurate measurements that are crucial in many industries, including engineering, manufacturing, and DIY projects. Unlike traditional calipers, digital calipers use electronic sensors to provide highly accurate readings and offer several advantages, such as easy-to-read digital displays and quick measurement conversion. Moreover, electronic digital calipers are designed to measure both external and internal dimensions, depths, and steps with high accuracy, making them indispensable in various applications.

Whether you need to measure the thickness of a piece of paper, the diameter of a bolt, or the depth of a hole – an electronic digital caliper will provide you with a reliable and precise measurement every time. Furthermore, electronic digital calipers are easy to use, lightweight, and versatile. They are portable and can be carried around in a toolbox or a pocket.

Additionally, they can switch between metric and imperial measurement units with the press of a button, making them suitable for use in different regions. In summary, if you need accurate and reliable measurements in your work or DIY projects, an electronic digital caliper is an indispensable tool. Its advantages over traditional calipers, including easy-to-read digital displays, quick measurement conversion, and the ability to measure both external and internal dimensions with high accuracy, make it the go-to tool for many professionals.

So, invest in an electronic digital caliper today and take your measurements to the next level!

Step-by-step Guide

Electronic digital calipers are a handy tool that can help you take precise measurements of small objects with ease. If you’ve never used one before, don’t worry – it’s simple and straightforward. Firstly, turn on the caliper and ensure that the display indicates “0.

00″. Place the object you want to measure between the jaws of the caliper, close them and take note of the measurement on the display. If you need to convert your measurements, most calipers have a mode button which allows you to switch between metric and imperial units.

It is also essential to keep the caliper clean and free of dust or debris that may interfere with the accuracy of your measurements. Whether you are a professional tradesperson or a DIY enthusiast, electronic digital calipers can save you time and frustration, and help you achieve a higher level of precision in your work.

Step 1: Turn On the Caliper

When it comes to using a caliper, it’s important to know how to turn it on properly. This step-by-step guide will walk you through the process. First, locate the on/off button, which is typically located on the top or side of the caliper.

Press and hold it down until the display screen lights up. Some calipers may have a zeroing button that must be pressed before the on/off button. Once the caliper is turned on, you’ll need to ensure that it’s reading correctly, which can be done by zeroing out the measurement or double-checking that it reads zero when the jaws are closed.

With the caliper turned on and calibrated, you’re ready to take accurate measurements. And that’s how you turn on a caliper – simple and easy!

Step 2: Zero the Caliper

When you start using a caliper, it’s essential to learn how to calibrate it. The first step towards calibrating a caliper is to zero it. The zero calibration provides an accurate starting point to measure dimensions.

Here’s a step-by-step guide on how to zero the caliper: Step 1: Turn on the caliper and close the jaws. Step 2: Press the “zero” or “tare” button. Step 3: The caliper display should show “0” or “000.

” Step 4: Open the jaws and check that the display stays at zero when there is no pressure on the jaws. It’s essential to zero the caliper before every measurement. This ensures that any deviations from the zero point are accounted for in the measurement.

It’s crucial to remember that even the slightest deviation can cause significant errors in the final measurement. So, take your time and double-check that the caliper is correctly zeroed before you start measuring anything. With this simple process, you’ll be ready to take accurate measurements in no time!

Step 3: Select the Measurement Mode

Now that you have properly set up your measuring tool, the next step is to select the appropriate measurement mode to get accurate results. There are different measurement modes available, depending on your measuring tool’s features and allowable functions. Some basic modes include length, area, volume, and angle.

Other advanced modes are specialized for specific applications, such as measuring vibration frequency, temperature, or electrical conductivity. To select the measurement mode, you need to refer to the user manual of your measuring tool. It will provide you with the steps required to activate each mode and the corresponding units of measurement.

Some measuring tools come with a digital display that automatically converts the raw data into the selected measurement mode, while others require manual conversion. Depending on your measuring needs, you may need to select multiple measurement modes to obtain comprehensive data. For instance, if you are measuring a room’s dimensions, you may need to use the length and area modes.

Alternatively, if you are measuring the thickness of a material, you may need the thickness and volume modes. Remember that selecting the right measurement mode is crucial for obtaining accurate readings. Using the wrong mode can skew the results and ultimately lead to unreliable data.

So, read through the user manual carefully, take your time, and select the appropriate mode for your measuring requirements. In conclusion, selecting the measurement mode is just as important as setting up your measuring tool. Make sure to refer to the user manual, understand the different modes available, and select the appropriate mode for your needs.

With this step out of the way, you are now ready to take measurements with confidence and accuracy.

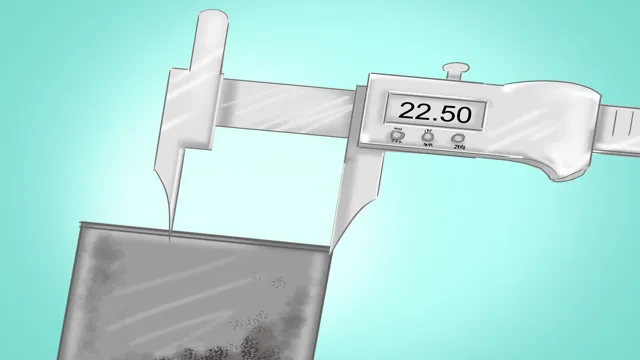

Step 4: Take the Measurement

Now that you’ve gathered all the necessary tools and prepared your work area, it’s time to take the measurement! This step is crucial in ensuring your project turns out just the way you want it. First, identify the area where you want to take the measurement and clear away any obstructions. Then, using your measuring tool, mark the starting point and stretch it to the end of the area.

Take note of the measurement in your preferred unit of measurement, and be sure to double-check it to avoid any discrepancies. Remember, always measure twice and cut once to avoid wasting materials. With your accurate measurement, you’re now ready to move on to the next step in your project!

Tips for Accurate Measurements

If you’re looking to take precise measurements, an electronic digital caliper can be a valuable tool to have on hand. But before you start using one, it’s important to make sure you’re doing it correctly. First, ensure that the caliper is zeroed out and properly calibrated before taking any measurements.

When placing the object you’re measuring into the caliper, be sure to keep it steady and make sure it’s flush against the measuring faces. Take multiple measurements to ensure accuracy and consistency. Additionally, be mindful of any parallax error by making sure you’re looking straight at the measurement display and not at an angle.

With these tips and some practice, you’ll be able to use an electronic digital caliper with confidence and precision.

Avoid Parallax Error

If you’re looking to take precise measurements, it’s essential to avoid parallax error. This is when the position of your eye affects your ability to read a measurement accurately. To avoid this, make sure your eye is directly in front of the measurement marker.

A helpful tip is to align your gaze parallel to the surface you’re measuring and avoid looking from an angle. Additionally, holding the measuring tool steady is essential. Any movement can cause parallax error, resulting in a poor and inaccurate measurement.

This error can lead to mistakes, which can be frustrating, especially in professional settings. Remember, avoiding parallax error is easy and essential to get accurate measurements you need for your projects.

Make Sure the Caliper Is Clean

When it comes to taking accurate measurements with a caliper, the cleanliness of the tool is crucial. Any dirt, oil, or debris on the caliper can cause inaccurate readings, which is the last thing you want. To make sure your caliper is clean, start by wiping it down with a soft, dry cloth.

Next, use a solvent or degreaser to remove any stubborn grime. Be sure to dry the caliper thoroughly before using it again. Additionally, it’s a good idea to store your caliper in a protective case or sleeve to prevent dust and other particles from settling on it.

By taking these simple steps, you’ll be able to ensure that your caliper is always in optimal condition for taking precise measurements.

Don’t Over-Tighten the Caliper

When using a caliper to take measurements, it’s important to be accurate. One key tip for achieving this accuracy is to avoid over-tightening the caliper. This may seem counterintuitive, but squeezing too hard on the object being measured can actually result in an incorrect measurement.

Instead, apply gentle pressure to the object and take your time to obtain a precise reading. It’s also a good idea to double-check your measurement by taking it in multiple locations on the object. By following these tips, you can ensure that your measurement is as accurate as possible.

So don’t rush, take your time, and you’ll be sure to get the precise measurement you need.

Conclusion

In conclusion, using an electronic digital caliper may seem daunting at first, but it’s really quite simple. Just remember to turn it on, zero it out, and use the jaws and depth probe to measure your object accurately. With this trusty tool by your side, you’ll never have to worry about inaccurate measurements again.

So go forth, measure with accuracy, and make precision your new best friend!”

FAQs

What is an electronic digital caliper?

An electronic digital caliper is a measuring tool used to accurately measure dimensions of different objects.

How to read an electronic digital caliper?

To read an electronic digital caliper, you need to turn it on, set the unit of measurement, use the jaws to measure the object, and read the measurement on the lcd screen.

What are the common mistakes to avoid while using electronic digital calipers?

The common mistakes to avoid while using electronic digital calipers are applying too much pressure, using it for rough measurements, and not zeroing it before a new measurement.

How to zero an electronic digital caliper?

To zero an electronic digital caliper, you need to close the jaws or place them on a flat surface, then press the zero button to set the reading to zero.

What are the different types of electronic digital calipers available in the market?

The different types of electronic digital calipers available in the market are vernier, dial, and digital calipers.

How to maintain and clean an electronic digital caliper?

To maintain and clean an electronic digital caliper, you should avoid dropping it, store it in a safe place, clean it with a dry cloth after each use, and lubricate it occasionally.

How to calibrate an electronic digital caliper?

To calibrate an electronic digital caliper, you can use a calibration block or a micrometer, follow the calibration instructions provided by the manufacturer, and make sure to repeat the process periodically.