How to Cut Perspex with Angle Grinder: Top Tips and Techniques

Cutting Perspex can be a tricky task, especially when you want to achieve a precise and clean cut. While there are various tools that can be used for the job, using an angle grinder can take your cutting experience to a whole new level. It’s not only faster and easier than other methods, but it also allows you to make cuts at any angle or shape, perfect for intricate designs or customized pieces.

It’s like having a sculptor’s tool in your hands, ready to turn a flat piece of Perspex into a remarkable masterpiece with every move. In this article, we’ll take a closer look at how to cut Perspex with an angle grinder, including tips and tricks for beginners and advanced DIYers alike. So, if you’re ready to explore the cutting possibilities of this powerful tool, keep reading!

What is Perspex?

Perspex is a type of acrylic sheet that is popularly used in various DIY and industrial projects as a replacement to glass. Due to its lightweight and durable nature, it is easier to handle, cut, and shape compared to glass. However, cutting perspex can be tricky, especially if you’re using an angle grinder.

Before starting, make sure you have the right blade for your angle grinder, and secure the sheet carefully to avoid slipping or cracking. Additionally, it is essential to wear protective equipment like gloves, goggles, and a dust mask while cutting perspex. With the proper tools, safety measures, and technique, you can successfully cut perspex with an angle grinder.

Just remember to go slow and steady, allowing the blade to cut through the material gradually.

Definition and Characteristics

Perspex is a type of acrylic plastic that is versatile, durable, and has become a popular alternative for glass. It has high transparency, which means that it is relatively clear and allows a lot of light to pass through. It also has high impact resistance, making it less likely to break, chip or crack.

This makes perspex ideal for a wide range of applications, including signage, display cases, windows, and even aquariums. Additionally, since perspex is lightweight and easier to work with than glass, it can be shaped, cut, and molded into virtually any shape or size. The keyword that is organically used in the content is Perspex.

Tools and Equipment Needed

If you’re looking to cut Perspex with an angle grinder, you’ll need a few tools and equipment to get started. Firstly, you’ll need a high-quality angle grinder that has a diamond cutting blade attachment. Make sure the blade size is suitable for the thickness of your Perspex sheets.

You’ll also need to wear appropriate personal protective equipment such as safety glasses, a dust mask, and earplugs. The Perspex sheets should be clamped securely to a workbench or other stable surface before beginning the cutting process. The key to successfully cutting Perspex with an angle grinder lies in using a slow and steady cutting speed, applying light pressure, and allowing the blade to do the work.

It’s also important to keep the Perspex sheet cool by using a water spray bottle or intermittently dipping the sheet into a bowl of water. With the right tools and a little bit of practice, cutting Perspex with an angle grinder can be a simple and effective task.

Angle Grinder and Required Attachments

An angle grinder is a versatile tool that can be used for a variety of cutting and grinding tasks. However, to get the most out of your angle grinder, you will need to invest in a few attachments. One of the most common attachments is the cutting disc, which allows you to cut through metal, tile, and other tough materials with ease.

Another popular attachment is the grinding wheel, which can be used for sharpening and grinding down metal surfaces. Depending on the job you are working on, you may also want to consider investing in a wire brush attachment for rust removal, a polishing disc for polishing metal surfaces, or a sanding disc for preparing surfaces for painting. While these attachments may seem like an added expense, investing in the right tools and equipment can save you time and effort in the long run.

So, before you start your next DIY project, make sure you have the right attachments for your angle grinder to ensure a job well done.

Safety Gear: Goggles, Gloves, Respirator

When working on any project that involves potentially harmful materials or substances, it is crucial to prioritize safety first. And one of the simplest but most effective ways to do so is by wearing the appropriate safety gear, which includes goggles, gloves, and a respirator. Goggles protect your eyes from debris, chemicals, and other irritants that may come into contact with them while working.

Gloves, on the other hand, shield your hands from cuts, burns, and exposure to hazardous materials. Lastly, a respirator ensures that you do not inhale any harmful dust or fumes while working. It is important to choose safety equipment that is right for the job and check that they are properly fitted.

By using the correct gear, you are taking a significant step towards preventing accidents and injuries. Always remember the importance of your health and safety while doing any tasks.

Preparing Perspex for Cutting

If you’re wondering how to cut Perspex with an angle grinder, the first step is to prepare the material properly. Perspex is a type of acrylic plastic that’s durable and resistant to shattering, but it can still crack or chip if not handled correctly. To prepare the Perspex for cutting, you’ll need to clean the surface and mark your cut line.

Use a ruler or straight edge and a marker to make a precise line where you want to cut. Additionally, it’s important to secure the Perspex firmly in place with clamps or a vice before cutting. This will prevent the material from slipping or vibrating during the cutting process, which could result in a crooked or uneven cut.

Once you’ve prepared the Perspex, you’re ready to start cutting with your angle grinder. Remember to wear protective gear like safety glasses and earplugs, and be cautious not to overheat the material or damage it with the grinder’s spinning blade. With these tips and a bit of practice, you can successfully cut Perspex with an angle grinder for your next project.

Marking the Cutting Line

When it comes to preparing perspex for cutting, one of the essential steps is marking the cutting line. This process is crucial in ensuring that your cut is precise and accurate. To begin, you’ll need to gather the necessary tools such as a ruler, marker pen, and masking tape.

First, determine the exact size and shape of the perspex, and ensure that you have the correct measurements before marking the cutting line. Next, use your ruler to draw a line along the cutting edge, ensuring that it’s straight and even. It’s also advisable to use masking tape to create a border around the cutting line, as this will help to prevent the perspex from cracking or splintering during the cutting process.

Remember to take your time to ensure that the marking is as accurate as possible. By marking the cutting line carefully, you’ll be able to avoid mistakes and ensure that your cutting process is a success!

Clamping the Perspex to a Work Surface

If you’re working with Perspex, it’s important to clamp it securely to your work surface before you start cutting. This ensures that your material stays steady and doesn’t move around during the cutting process, which could cause inaccurate cuts or even injury. To clamp Perspex, you’ll need a good quality clamp or two.

Place the Perspex onto your work surface and use the clamp to secure it into place, making sure that it’s tight enough that it won’t move. If you’re working on a larger piece of Perspex, you may need more than one clamp to secure it effectively. Once it’s clamped securely, you’re ready to start cutting.

Remember, take your time and don’t rush the process, as this will ensure that your cuts come out clean and accurate. With this method, you can confidently prepare your Perspex for cutting and ensure that your project will look professional and precise.

Cutting Perspex with an Angle Grinder

If you’re wondering how to cut perspex with an angle grinder, the process can seem intimidating at first. However, with the right materials and technique, it can be a relatively simple process. Firstly, make sure you have a good quality angle grinder with a fine-toothed blade, such as a diamond blade.

Then, use a ruler or straight edge to mark the cutting line on your perspex, ensuring it’s straight and even. Next, secure your perspex to a stable surface, such as a workbench, using clamps or a vice. Put on your safety goggles and position the angle grinder at the starting point of the cutting line.

Switch on the angle grinder and gently and steadily cut along the marked line. Use light pressure and take your time, ensuring that the perspex doesn’t overheat or warp. Voila! You now have a neat and precise cut.

Just remember to always follow safe practices and wear appropriate protective gear when using power tools.

Using the Diamond Disc

Cutting perspex with an angle grinder using a diamond disc can be a quick and easy way to achieve precise cuts. However, it’s important to take some safety precautions before you begin. Make sure to wear appropriate safety goggles and a dust mask to avoid inhaling any debris.

Use a guide or straight edge to keep your cutting line straight, and take breaks frequently to allow the perspex to cool down and prevent melting. It’s also worth noting that the diamond disc can generate a lot of heat, so be careful not to let it get too hot. Overall, cutting perspex with an angle grinder using a diamond disc can be a convenient and reliable method when done correctly.

Making a Small Cut to Start With

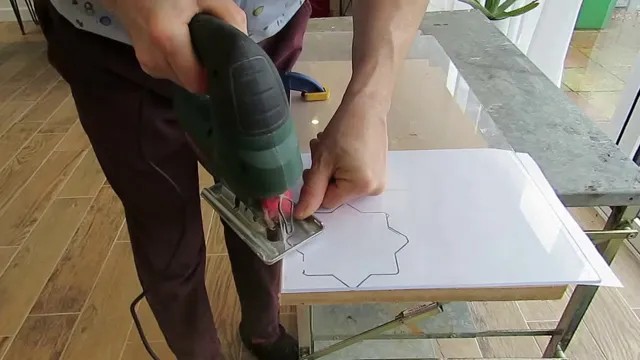

Cutting Perspex with an Angle Grinder is not as difficult as you might think. The trick is to make a small cut to start with. With a steady hand, carefully guide the angle grinder along the line you have marked on the Perspex.

Use light pressure and let the grinder do the work. It’s important to keep the grinder moving at a steady pace to prevent the Perspex from overheating. This can cause the material to warp or even crack.

By using a small cut, you can get a feel for how the Perspex is responding to the cutting process. It also gives you the opportunity to adjust your technique if necessary. While it may take some practice, cutting Perspex with an angle grinder is a great way to achieve precise cuts for all your DIY projects.

Following the Cutting Line

Cutting perspex with an angle grinder can be a daunting task, but with the right tools and techniques, it can be done successfully. First, ensure you have the correct cutting wheel for perspex and set the angle grinder to a low-speed setting. Using a ruler or straight edge, mark out the cutting line on the perspex and clamp it down securely to a workbench or surface.

Begin by making a shallow cut along the line, slowly increasing the depth until you have cut through the entire thickness of the sheet. It is important to follow the cutting line precisely and not force the angle grinder through the perspex to avoid cracking or damaging the sheet. With patience and the correct techniques, cutting perspex with an angle grinder can be a straightforward process.

Finishing Up

If you need to cut perspex with an angle grinder, there are a few steps you need to follow to ensure a smooth and efficient process. Before you begin, make sure you have the correct blade for cutting perspex. A diamond blade is recommended as it will reduce the risk of cracking or shattering the material.

It’s important to wear protective gear such as gloves, goggles, and a dust mask to prevent injury and exposure to harmful debris. Be sure to mark the perspex where you plan to cut it and secure it to a stable surface. Adjust the angle grinder to the appropriate speed and make a small indentation on the marked line before gently guiding the blade through the material.

Take breaks as needed to prevent overheating and continue until the entire piece has been cut. With the right equipment and precautions, cutting perspex with an angle grinder can be a simple and effective process.

Smoothening the Edges with Sandpaper

When it comes to woodworking, sandpaper is a crucial tool for achieving a smooth and flawless finish on your pieces. Once you have completed the main cutting and shaping stages, it’s time to pick up some sandpaper and start working on the finer details. Sandpaper comes in different grades, ranging from coarse to fine, and you’ll need to choose the appropriate one based on the wood type and desired finish.

With sandpaper, you can smoothen out any rough or jagged edges, eliminate scratches and blemishes, and create a uniform and professional look. Whether you’re a seasoned woodworker or a beginner, sandpaper is an essential part of any woodworking kit. So, the next time you’re trying to perfect your woodworking project, don’t forget to grab some sandpaper and start finishing up.

Cleaning the Perspex with a Cloth

Finishing up the process of cleaning Perspex requires a wiping cloth. When selecting a cloth, it is important to choose one that is soft and won’t scratch the surface. A microfiber cloth is an excellent choice.

Once you have your cloth, use it to wipe down the entire surface of the Perspex. Remember to wipe in a circular motion, and to do so gently. Be sure to pay attention to any areas that might have been missed during the initial cleaning process.

Once you have finished wiping down the Perspex, step back and admire your handiwork. The surface should now be shiny and clear, free from any dirt or grime. By taking the time to properly clean and maintain your Perspex, you can help ensure that it will look great for years to come.

Safety Precautions

If you need to cut Perspex with an angle grinder, it’s essential to take safety precautions to protect yourself and those around you. First, make sure you’re wearing the appropriate personal protective equipment, including safety glasses, gloves, and a dust mask. When cutting the Perspex, avoid cutting it too quickly or applying too much pressure to the grinder.

This can cause the Perspex to overheat and potentially crack or shatter. Instead, take your time and cut slowly and steadily. Make sure the Perspex is secured to a stable surface and avoid cutting near the edges to reduce the risk of breakage.

Use a vacuum cleaner or compressed air to remove any debris and dust particles, as they can be harmful if inhaled. Overall, it’s important to approach cutting Perspex with an angle grinder with caution and care to ensure a safe and successful outcome.

Avoiding Friction, Heat and Pressure Build-up

When working with machinery or tools, it is crucial to take safety precautions to avoid injury. Friction, heat, and pressure build-up can lead to dangerous situations, which is why it is essential to know how to prevent them. One way is to ensure that all machinery is adequately lubricated to reduce friction and wear.

It is also vital to monitor the temperature of equipment, as heat can cause burns or even fires. Workers should also be properly trained in the use of equipment to minimize the risk of accidents. In addition, wearing protective gear such as gloves and goggles can prevent injuries and provide an extra layer of safety.

By taking these safety precautions, workers can prevent accidents and stay safe while on the job.

Avoiding Electric Hazards

Electric hazards can be deadly, which is why safety precautions are essential. One of the most important things you can do to avoid electric hazards is to regularly check all electrical cords, outlets, and appliances for any signs of damage or wear and tear. Always unplug appliances when not in use, and never overload an outlet or extension cord.

If you are unsure about how to handle electrical repairs or installations, it is best to hire a licensed electrician. When working with electrical equipment, make sure your hands are dry and avoid standing in water, as water can conduct electricity. Additionally, be aware of your surroundings and never touch electrical equipment with wet hands or while standing on a wet surface.

Remember, taking care of your electrical equipment and being cautious is crucial to staying safe from electric hazards.

Proper Disposal of Perspex Scraps

When it comes to the proper disposal of Perspex scraps, safety precautions are vital. It is essential to wear the proper personal protective equipment (PPE) when handling Perspex scraps, such as gloves, goggles, and a mask, to avoid inhaling or coming into contact with harmful dust particles. Additionally, you should dispose of scraps in specialized waste containers, such as those with lids, to prevent accidental exposure.

In cases where it is not possible to dispose of Perspex scraps in dedicated containers, it is necessary to ensure that they are securely sealed in bags or packaging to prevent them from contaminating the environment. Remember, proper disposal of Perspex scraps is crucial, not only for our safety but also for the environment. By taking the necessary precautions, we can ensure that we are disposing of Perspex scraps in an eco-friendly and efficient way.

Conclusion

In conclusion, cutting perspex with an angle grinder may seem daunting but with the right preparation and technique, it can be a breeze. Remember to choose the right blade, take safety precautions, and take your time to ensure a clean cut. And if all else fails, just remember that sometimes a little bit of sandpaper and elbow grease can go a long way.

So go forth, and let the sparks fly (safely)! “

FAQs

What type of blade do I need to cut perspex with an angle grinder?

For cutting perspex with an angle grinder, it’s recommended to use a diamond-tipped blade.

What safety precautions should I take when cutting perspex with an angle grinder?

Always wear eye protection and a dust mask when cutting perspex. Make sure the material is firmly secured and the blade guard is in place.

Can I use a regular angle grinder to cut perspex?

It’s not recommended to use a regular angle grinder to cut perspex as it can cause the material to chip or crack. It’s best to use a specialized tool with a fine-cutting blade.

What is the best way to prevent melting while cutting perspex with an angle grinder?

To prevent melting, make sure to work slowly and avoid applying too much pressure. Use a lower speed setting on your angle grinder and take frequent breaks to let the material cool down.

How thick of a perspex sheet can I cut with an angle grinder?

The thickness of the perspex sheet that can be cut with an angle grinder depends on the size and power of your tool. It’s recommended to use a 4-inch angle grinder for sheets up to 1/4 inch thick and a 7-inch grinder for sheets up to 1/2 inch thick.

Is it necessary to use a lubricant when cutting perspex with an angle grinder?

Using a lubricant, such as water or a specialized cutting oil, can help reduce heat and prevent melting while cutting perspex with an angle grinder.

What is the best way to clean up after cutting perspex with an angle grinder?

Use a vacuum cleaner or a damp cloth to clean up any dust or debris left behind after cutting perspex with an angle grinder. Avoid using solvents or chemicals as they can damage the material.