How to Cut Metal Straight with Angle Grinder: Tips and Techniques

If you’re looking to cut metal straight with an angle grinder, you might feel overwhelmed by the tool’s power and efficiency. After all, an angle grinder is a versatile tool that can be used for a variety of tasks, but cutting metal can be a tricky ordeal. However, with a few tips and tricks, you can cut metal straight with ease and precision.

Firstly, it’s crucial to make sure you have the right blade for your angle grinder. There are several types of blades available, but for cutting metal, you want to opt for a diamond blade or a metal cutting blade. Make sure the blade is securely attached to your grinder before you begin.

Next, you’ll want to set up a stable work surface and secure your metal piece with clamps or a vice. It’s essential to keep your hands and body away from the blade at all times to avoid accidents. Once your setup is secure, it’s time to start cutting.

Slowly start moving the blade along your intended cut line, applying gentle pressure. Don’t rush the process; take your time and let the blade do the work. As you cut, periodically pause to remove any metal shavings that accumulate around the blade.

Remember to wear protective gear while cutting, such as safety glasses and gloves. Cutting metal with an angle grinder can be a loud and messy process, so be prepared for some noise and debris. With these tips in mind, you can confidently cut metal straight with an angle grinder.

Practice makes perfect, so don’t be discouraged if your first few attempts don’t turn out perfectly. Approach the task with patience and caution, and soon enough, you’ll be a pro at cutting metal like a pro.

Choose the Right Disc

If you plan on cutting metal with an angle grinder, it’s essential to choose the right disc for the job. The most common types of discs include metal-cutting, diamond, and abrasive discs. Metal-cutting discs are the most suitable for cutting through metal, while diamond discs are ideal for more heavy-duty projects.

Diamond discs are also excellent for cutting through thick materials and providing precision cuts. Abrasive discs are generally used for grinding down metal surfaces rather than cutting through them. Choosing the correct disc can make a huge difference in the outcome of your project.

Be sure to read the packaging carefully and follow the manufacturer’s instructions to ensure optimal performance and safety. With the right disc in hand, you can confidently cut metal straight with an angle grinder, delivering professional results.

Grinding Disc for Metal

When it comes to selecting the right grinding disc for metal, there are several factors to consider. The first thing you need to determine is the type of metal you are working with. Different metals have varying levels of hardness and toughness, which will affect the choice of grinding disc you need.

For instance, a mild steel will require a different disc than a hardened steel. Similarly, stainless steel may require a finer grit than cast iron. It’s also important to consider the size and thickness of the metal you’re working with as well as the precision of the job.

If you’re unsure which grinding disc to select, it’s always best to consult with an expert. With the right grinding disc, you can achieve the perfect finish on your metalwork and ensure long-lasting results.

Cutting Disc for Metal

Cutting metal can be a daunting task, but with the right cutting disc, it can be made much easier. When it comes to choosing the right disc for cutting metal, there are several factors to consider. The first thing to consider is the type of metal that you will be cutting, as there are different discs designed for different types of metal.

For example, a disc designed for cutting steel may not be suitable for cutting aluminum. It is also important to consider the thickness of the metal that you will be cutting. Thicker metal will require a thicker cutting disc in order to cut smoothly and efficiently.

Another factor to consider is the speed of the disc, as discs with high speeds can cut through metal more quickly, but may also produce more heat and wear out more quickly. Ultimately, the right cutting disc will depend on the specific task at hand, so it is important to carefully consider all of these factors when choosing a disc for cutting metal.

Prepare the Work Area

If you’re wondering how to cut metal straight with an angle grinder, the first step is to prepare your work area. Make sure you have a clean, flat surface to work on and protect it with a drop cloth or tarp. Use clamps or a vise to secure the metal piece to prevent it from moving while you cut.

Then, don’t forget to equip yourself with the necessary safety gear including eye protection, gloves, and a respirator mask to protect against dust and debris. Double-check that all equipment is in good working condition before getting started. Once everything is set up and ready to go, it’s time to learn how to make clean, straight cuts with your angle grinder.

Secure the Metal

When it comes to securing metal, it’s important to prepare the work area properly. This includes making sure the area is clear of any debris or obstacles that could impede your work. It’s also essential to wear appropriate safety gear, such as gloves and eye protection, to prevent injury while handling metal.

Additionally, you should have all the necessary tools and equipment on hand, such as clamps or vices, to securely hold the metal in place during the securing process. By taking the time to properly set up your work area, you’ll not only ensure your safety but also increase the likelihood of a successful and secure metal installation. Remember, taking shortcuts could lead to costly mistakes and injuries, so always prioritize safety and preparation.

Clear the Work Area

When it comes to any job, preparation is key. This is especially true when it comes to clearing a work area. Before beginning any kind of project, it is important to first prepare the space in which you’ll be working.

This means clearing out any clutter or debris and ensuring there is ample space to move around. Not only does a clear work area make the job at hand more manageable, it also promotes safety by removing any potential hazards. Whether you’re tackling a home renovation or working on a small DIY project, taking the time to prepare your work area is an essential first step towards ensuring a successful outcome.

So don’t skip this crucial step- taking a few minutes to clear the space could save you hours of frustration in the long run.

Mark the Cut Line

Cutting metal with an angle grinder can be a daunting task, especially for beginners. However, one of the most important ways to ensure that you achieve a straight cut is by marking the cut line accurately. The first thing you should do is to determine where the cut needs to be made, and then use a marker to draw a straight line on the metal surface.

This will act as a guide for your angle grinder and help you achieve a clean cut. Make sure to use a ruler or straight edge to make the line as straight as possible, as any variations can affect the result. Using masking tape can also help to keep the line visible and prevent it from being erased during the cutting process.

By marking the cut line correctly, you can ensure that your angle grinder cuts straight through the metal with ease, giving you the result you desire.

Use a Straight Edge

When it comes to cutting wood or any other material, using a straight edge is essential. Not only does it ensure that your cut is straight and even, but it also makes the process much easier and quicker. To mark the cut line accurately, simply place the straight edge where you want to make the cut and use a pencil to draw a line along the edge.

This will provide you with a clear guide to follow when making your cut. Whether you are using a circular saw, jigsaw, or any other cutting tool, having a clearly marked cut line will make the process much smoother and more precise. So, the next time you need to make a cut, be sure to use a straight edge and mark your cut line for perfect results every time.

Make Clear Marks

When working with wood or other materials, it is crucial to make clear marks to ensure a precise cut. Marking the cut line is an essential step that should not be overlooked. By using a pencil or marker, you can make a clear and visible line that will guide your saw or cutter throughout the process.

It is important to avoid making marks that are too faint or confusing, as this can lead to incorrect cuts and wasted materials. Take your time to mark the line carefully, using a ruler or straight edge if necessary. By putting in the extra effort to make clear marks, you can ensure that your cuts are accurate and achieve a professional-quality finish.

So, next time you’re preparing to make a cut, remember to take a moment to mark the cut line clearly for a job well done.

Start Cutting

If you’re looking to cut metal straight with an angle grinder, there are a few important steps to follow. First, make sure you have the right type of blade for the metal you’re cutting. You’ll want a thin, abrasive blade for sheet metal and a thicker, diamond-tipped blade for thicker metals.

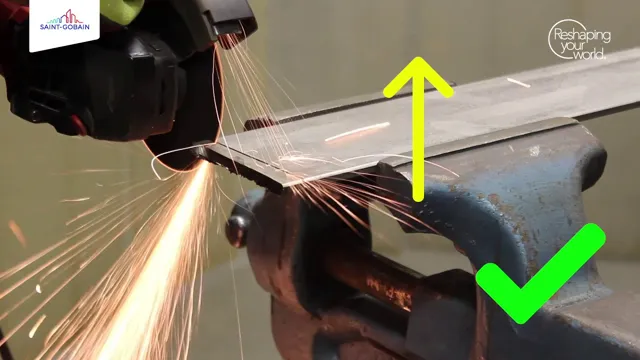

Next, clamp the piece of metal firmly to your work surface to prevent it from moving during the cutting process. When you’re ready to start cutting, turn on the grinder and slowly lower the blade onto the metal. Make sure to keep the angle of the grinder steady and use consistent pressure as you cut.

If you need to make a precise cut, you can mark the line you want to cut with a marker before you begin. Remember, safety is key when using an angle grinder. Always wear eye protection and work gloves, and make sure your workspace is clear of any potential hazards.

With these tips, you’ll be able to cut metal straight and accurately with your angle grinder in no time!

Start Slowly

Starting a new habit can be challenging, especially when it comes to cutting down on bad habits like smoking, drinking, or overeating. That’s why it’s important to start slowly and gradually ease yourself into the process. Going cold turkey can be overwhelming and increase the likelihood of relapse.

Instead, focus on small steps you can take to start cutting back. For example, if you’re trying to quit smoking, you can start by reducing the number of cigarettes you smoke each day. You can also try switching to a nicotine patch or gum to help curb cravings.

By starting slowly and building up your momentum, you’ll be more likely to succeed in the long run. So take it one step at a time and celebrate each small victory along the way.

Follow the Cut Line

Cutting is an essential process in various industries such as woodworking, metalworking, and textiles, among others. If you are new to cutting, you must identify the cut line before you start. The cut line is where you mark the material to guide the cutting tool, ensuring accurate cuts.

Start by measuring the material and marking the cut line using a pencil or marker. Ensure that the line is straight and visible. If you are using a saw, align the blade with the cut line and hold it steady before making a cut.

Use the appropriate cutting tool for the material you are cutting to achieve a clean and precise cut. Remember to prioritize your safety when cutting, wear protective clothing, and use the correct cutting technique to prevent accidents. Following the cut line is crucial to ensure that the final product meets your requirements.

Remember, practice makes perfect, and with time, you will master the art of cutting.

Finish and Clean Up

Cutting metal straight with an angle grinder can be a tricky business if you’re not familiar with the tool. However, with a bit of practice, you can master this skill in no time. To get started, you’ll need to make sure that you have the right disc for the job; a thin cut-off wheel or diamond blade is recommended.

Next, mark the cut-line using a marker or a scribe so that you have a clear guide to follow. Before you begin cutting, make sure that the metal is firmly secured in place and that you’re wearing appropriate safety gear such as gloves, eye protection, and a mask. When you’re ready to start cutting, hold the angle grinder firmly and apply gentle pressure to the metal, being careful to follow the marked line.

It can be helpful to use a square or straight edge as a guide to ensure a straight cut. As you cut, be sure to keep the angle grinder at a consistent angle and don’t rush the process. Once you’ve made the cut, use a file or a sandpaper to smooth out any rough edges.

Finally, clean up any metal shavings or debris so that you’re left with a clean and tidy workspace.

Turn Off the Angle Grinder

When you’re done using an angle grinder, it’s important to finish up and clean up properly. Turn off the grinder to avoid any accidents and unplug it from the power source. Let the grinder wheel come to a complete stop before setting it aside.

Once the grinder is no longer in use, get rid of any debris or waste that has accumulated during the job. Check the area thoroughly for any loose screws, nails, or other pointy objects that could cause harm. If your work area is indoors, make sure to sweep up any dust or debris and dispose of it properly.

If you’re working outside, use a hose to wash away any debris from the ground. Remember, a clean workspace is a safe workspace. Keeping everything tidy and organized will help prevent accidents and ensure that your tools remain in good working condition.

Let the Disc Cool Down

Let the disc cool down after use to ensure longevity. Not only will this prevent the disc from warping or cracking, but it will also help maintain the integrity of the data stored on it. Once you are finished with the disc, be sure to handle it with care to avoid damage.

Remove any fingerprints or smudges with a microfiber cloth to prevent any interference with the disc’s reading capabilities. Store the disc in a cool, dry place and avoid exposing it to direct sunlight or extreme temperatures. By taking these simple steps, you can ensure that your discs last for years to come, providing you with reliable storage for your important data.

Remember to always let the disc cool down and handle it with care to keep it in top condition.

Clean the Work Area

As you finish your work, it’s important to give the work area a good cleaning to ensure it’s ready for the next project. Cleaning up means properly stowing away tools, wiping down surfaces, and disposing of any waste material. Not only does this help maintain a neat and organized workspace, but it also ensures safety and helps extend the life of your tools.

Neglecting to clean up can lead to buildup of sawdust or debris, which can cause accidents or damage to tools. It’s important to take the time to properly clean up after a project to maintain a safe and efficient work environment. So, let’s not forget to put away our tools, sweep the sawdust off the floor and rubbish into the bin.

It’ll make the starting of next project much easier and pleasant.

Conclusion

And there you have it folks, cutting metal straight with an angle grinder isn’t rocket science, but it does require a bit of finesse and some practice. Just remember to take your time, mark your cut line, use a straight edge guide, and maintain a consistent pace and pressure. With these tips and a steady hand, you’ll be slicing through metal like a hot knife through butter.

So go forth and create precise cuts with your angle grinder, and don’t forget to show off your newfound skills to all your metalworking friends. As they say, a straight cut is a happy cut!”

FAQs

What kind of blade should I use to cut metal straight with an angle grinder?

Use a diamond blade or a metal cut-off wheel for best results.

What safety precautions should I take when cutting metal with an angle grinder?

Wear safety glasses, hearing protection, gloves, and a dust mask. Secure the metal being cut and make sure the grinder is securely held.

How do I attach the blade to the angle grinder?

Follow the manufacturer instructions to attach the blade securely to the grinder.

Can I cut curves with an angle grinder?

Yes, but it may be more difficult than straight cuts. Consider using a different tool for curves if possible.

What is the best technique for cutting metal with an angle grinder?

Use slow, steady motions and let the grinder do the work. Avoid pushing too hard or letting the blade get too hot.

What is the maximum thickness of metal I can cut with an angle grinder?

This will depend on the size and power of your grinder, as well as the blade you are using. Check the manufacturer’s recommendations.

Do I need to lubricate the blade when cutting metal with an angle grinder?

No, the blade does not need to be lubricated when cutting metal. However, you may need to clean it periodically to remove debris.