How Do Wiggins Clamps Work and Improve Efficiency in Engine Components?

Have you ever wondered how Wiggins clamps work and what makes them so effective? Look no further, because this complete guide will explain everything you need to know about these useful tools. Wiggins clamps, also known as quick release couplings, are innovative engineering marvels that use a unique design to provide a secure, leak-free connection between two hoses or pipes. From industrial air and water systems to high-performance race cars, Wiggins clamps are trusted by professionals across a wide range of industries.

In this guide, we will explore the science behind Wiggins clamps, how they are made, and their various applications. By the end of this article, you’ll have a thorough understanding of how Wiggins clamps work and why they are such an integral part of many machinery systems.

Overview of Wiggins Clamps

Wiggins clamps are widely used in heavy-duty industries such as aviation and motorsports where secure connections are essential. These clamps provide a tight, leak-proof connection between two parts, such as hoses and fittings, with minimal effort. But how do Wiggins clamps work? These clamps use a unique self-aligning design that makes them easy to install and remove, even in tight spaces.

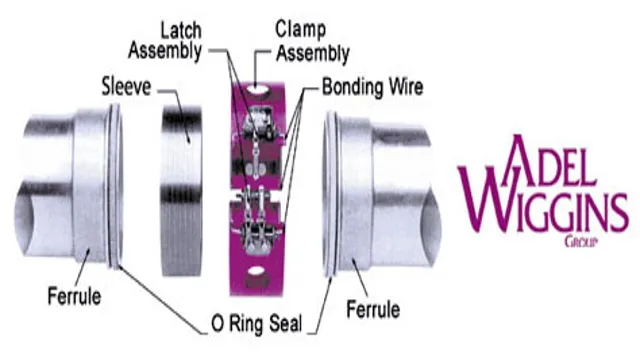

They consist of two main components: a clamp body and a collar that fits snugly over the fitting or hose. The collar is held in place by several spring-loaded locking segments that grip the fitting tightly, creating a strong and reliable seal. The clamp body has several small protrusions that engage with corresponding slots on the collar, ensuring proper alignment and preventing rotation.

Once installed, Wiggins clamps can withstand extreme temperatures and pressures without leaking or loosening. Overall, Wiggins clamps are a great choice for anyone in need of a durable, easy-to-install, and leak-proof fitting solution.

What Are Wiggins Clamps?

Wiggins clamps are a type of high-performance mechanical connector that is used to join pipes in various industries, such as aviation, automotive, marine, and industrial. These clamps have become increasingly popular in recent times due to their superior performance over conventional flange connectors. One of the key advantages of wiggins clamps is their ability to handle high pressure and temperature applications with ease.

They are also highly compact and lightweight, which makes them an ideal choice for applications where space is limited. Another advantage of wiggins clamps is that they are easy to install and require minimal maintenance. Overall, wiggins clamps are an excellent choice for any industry that requires a reliable and efficient pipe joining solution that can withstand high pressures and temperatures.

How Are Wiggins Clamps Used?

Wiggins clamps are a must-have item in many industries due to their versatility and durability. These clamps are widely used in hydraulic systems, fuel lines, and other applications that require high-pressure connections. They are known for their quick assembly and disassembly feature, making them convenient for any maintenance work.

Wiggins clamps come in different sizes and shapes to suit various applications, from small clamps used in automobiles to larger ones used in marine and aerospace industries. They work by applying a uniform pressure around the connection, ensuring a leak-free seal. Wiggins clamps are made from high-grade materials that can withstand extreme pressures, temperatures, and vibration, making them a reliable option for any application.

These clamps are easy to use, and their quick-connect design makes them ideal for industries where efficiency and safety are paramount.

Types of Wiggins Clamps

If you’re looking for a reliable way to connect hoses and pipes in the most efficient way possible, Wiggins Clamps could be your solution. These clamps use a roll-over design with a locking pin that creates a watertight and airtight seal. This means that even under high pressure, there won’t be any leaks, which is vital in many industrial and commercial applications.

There are a few different types of Wiggins Clamps available on the market, including T-handle clamps, quick release clamps, and locking collar clamps, all of which can be effective for different purposes. How do Wiggins Clamps work? When the clamp is tightened, the roll-over design causes the seal to compress, creating a tight and secure seal. The locking pin then slides into place, so the clamp can’t loosen and come apart.

These clamps are suitable for use in a wide range of industries, from aviation to motorsports and beyond. So, if you’re in need of a reliable hose or pipe connection, considering using Wiggins Clamps.

Single-Sided Wiggins Clamps

Single-Sided Wiggins Clamps are a type of clamp that has only one side that needs clamping. These clamps are popular in industries that require a secure and tight connection, such as aerospace, automotive, and marine industries. They work by connecting two tubes or pipes with a single clamp while ensuring a leak-proof seal.

The advantage of using these clamps is that they reduce weight and cost, as they require fewer components. Additionally, they provide easy access for maintenance and repair. There are different types of Wiggins Clamps, and the choice of clamp depends on the type of application.

Therefore, it is important to consult a professional in the field to ensure that the right type of clamp is used for the application. Whether you are working on an aircraft, a car, or a boat, Single-Sided Wiggins Clamps offer a secure and reliable solution for connecting tubes and pipes.

Double-Sided Wiggins Clamps

Wiggins clamps are a popular choice for connecting hoses and pipes in various industries. These clamps come in different types, one of them being the double-sided Wiggins clamp. Double-sided Wiggins clamps provide a secure and leak-free connection between two pipes or hoses.

They can be used for both suction and pressure applications and are commonly found in the marine, aviation, and agricultural industries. The design of these clamps enables them to handle high vibrations and extreme temperature changes without compromising the seal. The double-sided Wiggins clamp consists of two independent sleeves with a unique bead profile that ensures a quick and easy connection.

To install these clamps, the user simply needs to slide the two sleeves over the connecting pipes or hoses and then push them together. The clamps lock into place, creating a tight and reliable connection. So, if you are looking for a durable and efficient way to connect your hoses and pipes, the double-sided Wiggins clamp is definitely worth considering.

Triple-Sided Wiggins Clamps

Wiggins Clamps Are you searching for a reliable, high-quality clamp for your industrial or automotive needs? Look no further than Wiggins Clamps. There are several types of Wiggins Clamps available, including the popular Triple-Sided Wiggins Clamp. This innovative design features three sides for maximum grip, ensuring a tight seal and preventing leaks.

Whether you are working with hoses, pipes, or other components, the Triple-Sided Wiggins Clamp is an excellent choice. With its durable construction and easy-to-use design, you can rely on this clamp for all of your heavy-duty applications. So why settle for a subpar clamp when you can have the best? Choose Wiggins Clamps, and get the job done right the first time.

How Wiggins Clamps Work

If you’re working in an automotive or industrial field, you’re probably familiar with Wiggins clamps. These clamps are specially designed to securely connect hoses and pipes, preventing leaks and maintaining a continuous flow of fluids. So how do Wiggins clamps work? The secret lies in the geometry of the clamp itself.

Wiggins clamps are made up of two main components: a grooved collar and a retaining ring. The collar is designed to fit snugly around the hose or pipe, while the ring fits into grooves on the collar and is tightened with a bolt or other fastener. This creates a tight seal that keeps fluids flowing smoothly and prevents leaks from occurring.

Additionally, the shape of the collar and retaining ring is designed to evenly distribute pressure around the hose or pipe, reducing the risk of damage or deformation and maximizing the lifespan of the clamp. With their simple yet effective design, Wiggins clamps are a staple in many industries and play a crucial role in keeping machinery and vehicles running smoothly.

Application of Pressure

Wiggins clamps are used for creating high-pressure connections in hydraulic systems, and they work by applying compression on a synthetic rubber seal that is squeezed between two metal plates. When the clamp is tightened, the plates come together and press the seal, creating a tight, leak-proof connection. The clamps are designed to withstand a wide range of temperatures, pressures, and chemical exposures, making them ideal for use in a variety of industrial applications.

The secret behind the Wiggins Clamps is that the seal is designed to expand and contract with changes in temperature and pressure, ensuring a reliable connection even in demanding conditions. Whether you’re working in the oil and gas, mining, or aerospace industries, Wiggins Clamps can help you create secure, durable, and efficient hydraulic connections that will stand the test of time.

Leak-Free Sealing

Wiggins clamps are a popular sealing method used in a variety of industries, including automotive and aerospace. These clamps work by using a convex metal ring that applies pressure to a mating surface, creating a leak-free seal. The design of the clamp allows for flexibility and adjustability, ensuring a tight seal regardless of any small imperfections in the mating surfaces.

The use of Wiggins clamps can provide several benefits, including reduced maintenance costs and improved system reliability. Additionally, these clamps are easy to install and can be quickly and easily replaced if needed. So, if you’re looking for an effective sealing solution, consider using Wiggins clamps for your next project.

Advantages of Wiggins Clamps

Wiggins clamps are a popular type of hose clamp that are used in a variety of applications. They work by applying pressure to the hose and creating a tight seal. This is achieved through the use of a spring-loaded mechanism that clamps down on the hose as it is tightened.

The advantages of Wiggins clamps include their ability to provide a secure and leak-free seal that is resistant to vibration and movement. Additionally, they are easy to install and can be repositioned or removed quickly if needed. They are also durable and can withstand extreme temperatures and harsh environments.

The design of Wiggins clamps allows for a tighter and more secure seal than other types of hose clamps, making them an excellent choice for high-performance applications. Overall, Wiggins clamps are a reliable and effective solution for preventing leaks and ensuring the proper functioning of hydraulic and fluid systems.

Reduced Maintenance Costs

Reduced Maintenance Costs Wiggins clamps offer a range of advantages that make them a top choice for many industries. One of the biggest benefits is reduced maintenance costs. This is because Wiggins clamps are designed to last a long time without needing repairs or replacements.

Unlike other clamps that may wear out quickly or fail under heavy use, Wiggins clamps are built to withstand even the harshest conditions. This means you won’t have to spend as much time and money on maintenance, which can save you a lot of hassle in the long run. And if you do need to make any repairs, Wiggins clamps are easy to work with and can be fixed quickly.

Overall, the reduced maintenance costs of Wiggins clamps make them a smart investment for any business looking to save time and money in the long run. So why not give them a try and see how they can benefit your operations?

Increased Efficiency

Wiggins Clamps are known for providing increased efficiency in various industries, making them a popular choice for many professionals. One of the advantages of Wiggins Clamps is their ability to quickly and easily connect and disconnect hoses and pipes, saving valuable time that can be used for other tasks. The design of Wiggins Clamps also minimizes leaks, which not only prevents accidents but also reduces the need for frequent maintenance and repairs.

Additionally, the clamps are made with durable materials, allowing them to withstand high pressure and extreme temperatures. This means that once they are installed, they can be relied on for long periods without needing to be replaced. With all these benefits, it’s clear why Wiggins Clamps are a go-to option for improving efficiency in various industries.

Conclusion

In conclusion, Wiggins clamps work by utilizing a clever combination of tension and compression, much like the perfect mixture of peanut butter and jelly in a sandwich. By evenly distributing force across the surface area of a joint, they create a strong and secure hold that is essential for a wide variety of mechanical applications. So whether you’re an engineer, a mechanic, or just a curious observer, next time you marvel at the ingenuity of a Wiggins clamp, just remember – it’s all about finding that perfect balance.

“

FAQs

What are Wiggins clamps?

Wiggins clamps are a type of quick connect and disconnect fitting that use a gasket and a metal clamp to create a tight seal between two pipes or hoses.

How do Wiggins clamps work?

Wiggins clamps work by compressing a gasket between two flanges, which creates a tight, leak-free seal. The clamps are tightened using a common wrench or torque wrench, and can be easily removed with a special release tool.

What materials are Wiggins clamps made from?

Wiggins clamps are typically made from aluminum or stainless steel, with gaskets made from a variety of materials depending on the application, such as EPDM, Buna-N, or Viton.

What industries use Wiggins clamps?

Wiggins clamps are commonly used in industries such as agriculture, construction, trucking, and marine, where rapid connections and disconnections of hoses and pipes are required for efficient operation.

Are Wiggins clamps reusable?

Yes, Wiggins clamps are designed to be reusable, since the gasket can be replaced as needed. However, it is important to inspect the gasket and clamp for damage or wear before reusing them.

What sizes are available for Wiggins clamps?

Wiggins clamps are available in a wide range of sizes, from 2″ to 12″ diameter, and can be customized to fit specific applications.

Can Wiggins clamps be used for high-pressure applications?

Yes, Wiggins clamps can be used for high-pressure applications, as long as the appropriate gasket and clamp are selected for the specific pressure range and fluid being transported.