How Do V Band Clamps Work in Exhaust Systems: A Comprehensive Guide

Do you know what keeps your car’s exhaust system tightly sealed and free from leakages? It’s V band clamps! Despite their importance, not many vehicle owners are aware of these handy clamps and their function. V band clamps are used in a variety of applications, from motorsports to industrial equipment, to hold together pipes and tubing. They offer a robust, secure, and leak-proof connection between two parts of the exhaust system, ensuring that harmful emissions stay contained and don’t pollute the environment.

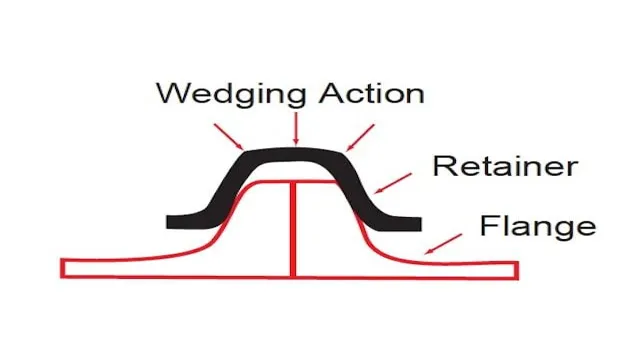

V band clamps got their name from their shape, which resembles a letter V. They consist of two metal rings, one with a protruding flange and the other with a recessed flange. The flanges lock together and compress a gasket to create a tight seal.

Since V band clamps don’t require any bolts or nuts, they are easy to install and remove, making them a popular choice in racing and high-performance vehicles. One of the biggest advantages of V band clamps is their flexibility. They can be used in a variety of positions and orientations without compromising their sealing ability.

Additionally, V band clamps are resistant to high temperatures, vibrations, and corrosion, which is why they last longer than traditional exhaust clamps. In conclusion, V band clamps are a crucial component of the exhaust system that ensures a tight and leak-free connection between pipes. If you want to upgrade your vehicle’s exhaust system or replace faulty clamps, V band clamps are an excellent choice.

Not only are they easy to install and remove, but they also offer superior sealing, flexibility, and durability.

Introduction to V Band Clamps

V-band clamps are versatile and effective tools for joining pipes, tubes, or other cylindrical objects together. They consist of two circular clamping flanges, one of which has a protruding lip that fits into the other’s groove, creating a secure, leak-proof seal. The V-shape design of the clamp allows it to exert pressure evenly, distributing the force and ensuring a tight connection.

These clamps are quick and easy to install, making them a popular choice for automotive and exhaust applications. They are also commonly used in industrial and aerospace settings because of their reliability and durability. V-band clamps can withstand high temperatures and pressures, making them an ideal choice for harsh working environments.

Overall, how do V-band clamps work? They provide a simple, effective method of connecting cylindrical objects that require a secure seal and can withstand severe conditions without compromising the connection.

Definition of V Band Clamps

V band clamps are essential fastening tools used in different industries, including automotive, marine, and industrial applications. They consist of a steel or stainless-steel band with a V-shaped groove, a flange, and a latch mechanism that secures the clamp. V band clamps are reliable, easy to install and remove, and can withstand high temperatures and vibrations.

They are commonly used in exhaust systems, turbocharger connections, intercooler pipes, and other applications that require a secure, leak-free joint. The V-shaped groove design allows for a tight seal, preventing exhaust leaks and reducing noise and emissions. Overall, V band clamps provide a cost-effective, efficient, and convenient solution for joining pipes and other components.

Components of V Band Clamps

V band clamps are used to connect two pipes or tubes together in various industries. These clamps are made up of a few different components that work together to create a secure and reliable connection. The main components of a V band clamp include the clamp itself, which is typically made of stainless steel and shaped like a V, and the flange, which is flat and also made of stainless steel.

The flange fits onto the pipes or tubes being connected and is held in place by the clamp. Additionally, some V band clamps come with a gasket, which helps to create a tight seal between the pipes or tubes. The V band clamp is a great solution for those looking for an easy-to-use and reliable method of connecting pipes or tubes.

How V Band Clamps Work

If you’ve ever worked with automotive exhaust systems, there’s a good chance you’ve come across V band clamps. These unique clamps are designed to securely fasten two pipes together, typically in an exhaust system. But how do V band clamps work, exactly? Well, the key to these clamps is their shape.

The clamp itself is circular, with a flared, V-shaped groove on one end. The two pipes or components being joined together also have corresponding V-shaped grooves, which fit snugly into the clamp’s groove. Once the components are in place, the clamp is tightened using a bolt or other fastener, compressing the grooves together and creating a strong, leak-free seal.

What makes V band clamps so useful is their ease of use and versatility. Unlike other types of clamps, they can be quickly and easily installed and removed, making them ideal for applications where components need to be frequently replaced or adjusted. Additionally, their strong seal ensures that no exhaust or other gasses escape between the pipes, reducing noise and pollution.

Overall, V band clamps are a great solution for anyone working with exhaust systems or other pipe-based assemblies.

Assembly Process of V Band Clamps

V band clamps are a popular choice for connecting pipes in various automotive and industrial applications. These clamps consist of two circular bands made of stainless steel or aluminum that press together to seal the connection. The assembly process of V band clamps is relatively simple, starting with the placement of the V shaped groove around the pipe or joint that needs to be connected.

The first band is then placed around the groove and tightened with a bolt or clamp until it fits snugly around the pipe. The second band is placed on top of the first one and tightened in the same manner. Once both bands are secured, they create a tight seal that prevents any leaks or movement of the pipes.

The unique design of V band clamps is what makes them so effective. The V shaped groove allows the clamp to fit snugly around the pipe, creating an airtight seal that is resistant to vibrations and movements. Unlike traditional bolt clamps, V band clamps can be easily installed and removed without the need for tools, making them an ideal choice for situations where frequent maintenance is required.

Whether you are working on a race car or a heavy-duty industrial application, V band clamps are a reliable and efficient solution for connecting pipes and ensuring optimal performance. In conclusion, the assembly process of V band clamps is simple yet effective, and their unique design makes them an ideal choice for various applications. Their ability to create a tight seal around pipes and resist vibrations and movements makes them a reliable and efficient option for connecting pipes.

Whether you are working on a race car or an industrial application, V band clamps offer an easy-to-use solution that will help ensure optimal performance. So, next time you are in need of a pipe connection, consider using V band clamps for a quick and hassle-free installation process.

Functionality of V Band Clamps

V Band Clamps V Band Clamps are a highly effective way of joining two pipes together. The clamps work by wrapping around the two pipes and tightening to create a strong seal that keeps the pipes securely in place. V Band Clamps are designed to be easy to install and remove, using a simple locking mechanism that is quick and straightforward to operate.

The clamps are used in a wide range of applications, including automotive, industrial, and aerospace. The main benefit of using V Band Clamps is their ability to create a tight seal that prevents leaks and ensures that the pipes remain firmly in place. V Band Clamps are also durable and long-lasting, making them a reliable solution for a variety of applications.

Whether you are looking to repair a broken exhaust system or secure pipes in a manufacturing environment, V Band Clamps offer a simple, effective solution that is sure to meet your needs.

Advantages of V Band Clamps

V Band Clamps V Band Clamps are widely used in various industries due to their effectiveness and reliability. These clamps consist of two mating flanges, each containing a V-shaped groove, and a flexible metal or elastomeric seal that fits into the groove. When these two flanges are bolted together, the seal compresses, creating a tight and leak-proof joint.

The advantages of V Band Clamps are numerous. Firstly, they provide a quick and easy way to assemble and disassemble components, reducing maintenance downtime. Secondly, they offer superior sealing performance compared to other clamping methods, ensuring a leak-proof joint even under high temperatures and pressures.

Additionally, V Band Clamps are highly flexible and can accommodate misalignment between the mating flanges, making them ideal for use in exhaust systems. Finally, V Band Clamps have a compact design, allowing for easy installation in tight spaces. Consequently, it’s easy to see why V Band Clamps are the go-to choice for many industries seeking a reliable and effective clamping solution.

Common Applications of V Band Clamps

V band clamps are used in a wide range of applications that require a reliable and effective sealing solution. These clamps work by using a V-shaped coupling that connects two pipes or tubes together. The clamp is secured around the pipes using a bolt, which is tightened to create a compressive force that seals the joint.

One of the most common applications for V band clamps is in exhaust systems, where they are used to join sections of the exhaust pipe together. They are also used in turbocharged applications, where they are used to connect the turbocharger to the exhaust manifold. Other applications of V band clamps include in industrial piping, HVAC systems, and aerospace.

The design of these clamps makes them highly effective at preventing leaks and offering excellent resistance to vibration and thermal expansion. Overall, V band clamps are a versatile and reliable solution for a wide range of applications.

Exhaust Systems

Exhaust systems are an integral part of any vehicle as they effectively remove waste gases produced by the engine. For such a vital component, it’s important to ensure it is held in place with a sturdy clamp. V-band clamps serve this purpose seamlessly as they offer a quick, simple, and effective solution.

They are commonly used on turbochargers, exhaust manifolds, and downpipes. Additionally, V-band clamps allow for easier maintenance as they permit easier access to the exhaust system, which traditional bolt clamps do not offer. These clamps are built to endure high-pressure conditions and high temperatures, making them the ideal option for exhaust systems.

They provide a reliable solution against exhaust leaks and any other potential engine malfunctions that may occur. V-band clamps are beneficial for car enthusiasts who want to upgrade their vehicle’s exhaust system for increased performance since they are easily adjustable and provide a tight seal. Overall, V-band clamps are an excellent option for maintaining your vehicle’s exhaust system, ensuring it functions safely and effectively.

Industrial Applications

V band clamps are widely used in various industrial applications due to their excellent capabilities to withstand high pressure, temperature, and vibration. One of the common applications of V band clamps is in the automotive industry where they are utilized to secure exhaust systems, turbochargers, and intercoolers. These clamps come in handy in challenging environments, providing a reliable and durable solution that can withstand extreme temperatures, vibration, and pressure.

V band clamps are also used in the aerospace industry, where they are preferred for joining complex components in the engine, turbine sections, and exhaust systems. The food and dairy industry also use V band clamps to join pipes and provide fast and effective cleaning and maintenance. This clamp’s versatility and ease of use make it an ideal solution for several applications where secure and robust joints are necessary.

Choosing the Right V Band Clamps for Your Application

“V band clamps work by providing a secure, leak-free joint between two pipes or flanges in a variety of applications. By using a V-shaped clamp and a matching flange with a groove, the clamp’s outer band can be tightened around the flange, compressing the joint and creating a seal. The clamp’s design also provides a strong mechanical connection that can withstand high temperatures, pressure, and vibrations.

When choosing the right V band clamp for your application, it’s essential to consider factors like the diameter and material of the pipes or flanges, the temperature and pressure of the system, and the degree of shock and vibration present. This will help ensure that you select a clamp that can provide the necessary strength and durability, as well as prevent costly leaks or failures down the line. Overall, V band clamps are a reliable and efficient way to create a tight seal between pipes or flanges in a wide range of industries, from automotive and aerospace to industrial and marine.

“

Conclusion

In summary, V band clamps are like the fairy godmothers of exhaust systems. They hold everything together with a firm grip, but also allow for easy disassembly, making them the perfect solution for frequent tinkering and modifications. They’re the ultimate wingmen of the automotive world, ensuring that your exhaust system looks and performs its best, all while adding a touch of magic to the process.

“

FAQs

What are V band clamps used for?

V band clamps are typically used in automotive and industrial applications to connect pipes or tubes together securely.

How do V band clamps work?

V band clamps work by using a circular clamp with a v-shaped groove on one end and a flange on the other to hold pipes or tubes together. The clamp is tightened using a nut or bolt, which compresses the v-groove onto the flange, creating a tight seal.

What materials are V band clamps made from?

V band clamps can be made from a variety of materials including stainless steel, aluminum, and titanium. The material used for the clamp will depend on the application and the desired strength and durability.

Can V band clamps be reused?

Yes, V band clamps can be reused as long as they are not damaged or worn. It is recommended to inspect the clamp for any damage before reusing it.

What size V band clamp do I need for my application?

The size of the V band clamp needed for a specific application will depend on the diameter of the pipe or tube being connected. It is important to measure the diameter accurately to ensure the correct size clamp is used.

Are V band clamps easy to install?

Yes, V band clamps are relatively easy to install and can be done without any special tools or equipment. However, it is important to follow the manufacturer’s instructions carefully to ensure the clamp is installed correctly.

Can V band clamps be used in high temperature applications?

Yes, V band clamps can be used in high temperature applications as long as the material used for the clamp is suitable for the temperature range. Stainless steel and titanium are commonly used for high temperature applications.