How Do Bar Clamps Work? A Beginner’s Guide to Understanding Bar Clamp Mechanisms

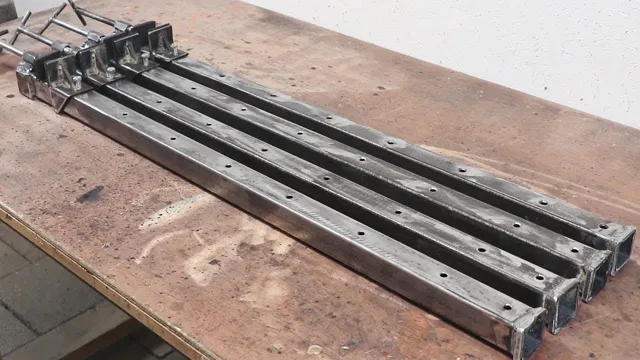

If you’re one of those DIY enthusiasts who love to build furniture, tools, or other fixtures, then you’ve probably heard of bar clamps. Bar clamps are one of the most essential tools in a woodworker’s toolkit that allows you to hold pieces of wood or metal together firmly and securely while you work on them. But how do bar clamps work, and why are they so useful? To put it simply, bar clamps work by using a long steel or aluminum bar to apply pressure on a workpiece, keeping it in place while you work with it.

They have adjustable jaws that can accommodate different sizes of materials, and the tension can be adjusted as well by tightening or loosening the screw. The best thing about bar clamps is their versatility. You can use them to clamp pieces of wood together while you glue them, hold a metal piece in place while you weld it, or secure a workpiece to a table while you drill or sand it.

They are also much more powerful than other types of clamps, ensuring that your workpiece stays in place no matter how much force you apply. So if you’re a woodworker or a DIY enthusiast, a bar clamp is an absolute must-have. It’s a tool that will make your work much easier and more efficient, allowing you to create high-quality pieces that will last for years.

Start exploring the world of bar clamps today, and see how versatile and useful they can be!

Introduction

Have you ever wondered how bar clamps work? Bar clamps are a highly versatile tool used for clamping two objects together. They consist of a long bar with a fixed jaw on one end and a sliding jaw on the other end. The sliding jaw can be moved along the bar to accommodate objects of varying sizes.

To use the clamp, the fixed jaw is placed on one object, and the sliding jaw is placed on the other object. The user then tightens the clamp by turning a handle or twisting a knob, which causes the sliding jaw to move towards the fixed jaw, applying pressure to the objects. Bar clamps are commonly used in woodworking projects, metalworking, welding, and many other applications where a strong and secure hold is needed.

When you need to hold two objects firmly together, bar clamps provide a reliable and easy-to-use solution.

Definition of Bar Clamps

Bar clamps are an essential tool in any woodworker or carpenter’s toolkit – they are versatile and an easy way to hold two or more pieces of material together while glue dries or while the material is being worked on. Bar clamps are a type of clamp that uses a bar or a pipe as the main mechanism to hold pieces of wood or metal together. They are available in different sizes and shapes, and they can fit a wide variety of projects.

One of the notable features of bar clamps is their ability to apply pressure evenly across the workpiece. This even pressure results in a secure hold, preventing the workpiece from moving during clamping. Additionally, bar clamps can be modified to add custom jaws or extended clamping capacity using a small amount of time and effort.

Overview of Bar Clamp Components

Bar clamps are an essential tool in any woodworking or metalworking shop. These clamps are designed to provide a secure grip on materials, making it easy to work with them. There are many different components that make up a bar clamp, including the screw, the handle, the jaw, and the bar itself.

The screw is used to tighten the clamp onto the material, while the handle provides the user with the leverage needed to do so. The jaw of the clamp is typically covered in rubber or another type of material that will not damage the surface of the material being clamped. Finally, the bar is what connects all of these components and allows the clamp to be adjusted to the desired length.

By understanding how these different components work together, you can choose the right bar clamp for your needs and ensure that you get the best results possible. Whether you are a professional woodworker or just starting out, a good set of bar clamps is a must-have for any workshop.

Using Bar Clamps

If you’ve ever wondered how bar clamps work, you’re not alone. These essential tools are a staple in any workshop or DIY project, but to the uninitiated, they can seem a bit intimidating. Essentially, bar clamps work by using a long metal bar as a guide to hold two pieces of wood (or other materials) together tightly.

The bar is threaded through a clamp mechanism, which can be tightened or loosened as needed to adjust the pressure on the wood. This makes bar clamps extremely versatile, as they can be used for a wide range of projects and applications. Whether you’re building a simple bookshelf or a complicated piece of furniture, bar clamps are an indispensable tool that can help you get the job done right.

So next time you’re wondering how to clamp two pieces of wood together, remember that bar clamps are your go-to solution for achieving a tight, secure fit every time.

Step-by-Step Instructions for Using Bar Clamps

Bar clamps are an indispensable tool for anyone working on woodworking projects or in the construction field. They’re versatile, easy to use and offer excellent strength. But if you’re new to using bar clamps, it can be a bit overwhelming.

Here’s a step-by-step guide on how to use bar clamps like a pro. First, select the correct size based on your project’s needs, ensuring it can handle the necessary clamping force. Place the workpieces together and position the clamp across them, making sure the clamp aligns perpendicular to the joint.

Tighten the clamp until it’s snug, ensuring that the pressure is evenly distributed between the workpieces. Finally, check the position of the clamp and adjust as needed until it’s evenly aligned with the joint. With a little practice, you’ll find that bar clamps are an easy and effective way to create a strong, sturdy joint that will last for years.

Common Uses for Bar Clamps

Bar clamps are versatile and useful tools for a variety of applications. One of the most common uses for bar clamps is in woodworking, where they are used to hold pieces of wood together while glue dries. They can also be used to hold pieces of metal or other materials together while welding or soldering.

Bar clamps are adjustable, which means they can be tightened or loosened to fit different sizes of material. This makes them useful for a wide range of projects, including furniture building, cabinetry, and even home repairs. Overall, bar clamps are an essential tool for anyone who wants to get serious about DIY projects and repairs.

Types and Variations of Bar Clamps

Bar clamps are an essential tool for any woodworker or DIY enthusiast. They work by using a longer bar as leverage to clamp down on an object, keeping it securely in place. There are several types and variations of bar clamps available, each with its own unique features.

The most common type is the F-clamp, which has a fixed bar on one side and a sliding bar with a clamp on the other. Another type is the trigger clamp, which uses a trigger mechanism to tighten and release the clamp. A third type is the parallel clamp, which has jaws that remain parallel to each other, allowing for greater stability and precision.

Bar clamps also come in different sizes, with lengths ranging from six inches to over four feet, making them versatile for a wide range of projects. Overall, bar clamps are a reliable and straightforward tool for holding objects in place during woodworking or DIY projects.

Parallel Clamps vs. F-Style Clamps

Bar Clamps When it comes to woodworking or any type of DIY projects, clamps are an essential tool. Bar clamps are among the most popular types of clamps available, and they come in a variety of shapes and sizes to suit different projects. Two common types of bar clamps are parallel clamps and F-style clamps.

Parallel clamps are designed for larger projects and offer a clean and even clamping pressure. They are commonly used for gluing and assembly work and are popular among woodworkers. Meanwhile, F-style clamps are more flexible and can be used for a wide variety of tasks.

They come in many sizes, making them suitable for small and large projects alike. They are characterized by their “F” shape and are versatile enough to be used in many different projects. Ultimately, the type of bar clamp you choose will depend on the specific task at hand.

However, both parallel clamps and F-style clamps are excellent choices for anyone working with wood or metal. Whether you’re a professional woodworker or a beginner DIY enthusiast, bar clamps are an essential tool to have in your workshop.

Trigger Clamps vs. Screw Clamps

When it comes to woodworking and metalworking, bar clamps are crucial tools that help to keep the workpiece stable and secure. There are two main types of bar clamps: trigger clamps and screw clamps. Trigger clamps have a trigger mechanism that allows for quick and easy clamping and releasing, making them a popular choice for those who work on smaller projects.

On the other hand, screw clamps have a rotating handle or crank that enables the user to adjust the clamp and apply the necessary pressure. One advantage of screw clamps is their ability to hold larger workpieces more securely, making them ideal for heavy-duty projects. Both types of bar clamps come in various sizes and designs to suit different applications and budgets.

Some of the most common variations include parallel clamps, pipe clamps, and quick-release clamps. At the end of the day, the type of bar clamp you choose depends on the task at hand, the size and weight of the workpiece, and your personal preferences. Whether you opt for a trigger clamp or a screw clamp, using the right tool can make a world of difference in the quality and accuracy of your work.

Specialty Bar Clamps

When it comes to woodworking, bar clamps are essential tools to have in your arsenal. They come in various types and variations, but specialty bar clamps are among the most useful. These clamps are designed to provide added functionality and ease of use.

For instance, one of the most common types is the pipe clamp, which has a cylinder-shaped head that fits onto a length of pipe. The pipe can be adjusted to any length, allowing you to clamp larger projects with ease. Another popular type of specialty bar clamp is the quick-release clamp.

As the name suggests, it enables you to release the clamp quickly, which can be especially handy when you are working with large projects. Ultimately, the type of specialty bar clamp you choose will depend on your needs and the type of woodworking you are doing. So, do some research, and invest in the right specialty bar clamps to get the job done right.

Conclusion

In conclusion, bar clamps are like the superheroes of the woodworking world, using their strong and sturdy bodies to hold pieces of wood firmly in place. They work by utilizing their long, flat bars and adjustable clamp heads to create an unbreakable holding force. It’s like magic, only with steel and brute force! So the next time you’re creating a woodworking masterpiece, rest assured that your trusty bar clamp has got your back (or rather, your wood)!”

FAQs

What are bar clamps and how do they work?

Bar clamps are tools that are used to hold and secure materials in place during woodworking or metalworking. They work by using a sliding bar and a stationary jaw to apply pressure and hold materials in place.

What are the different types of bar clamps?

There are several types of bar clamps, including F-clamps, parallel clamps, pipe clamps, and quick-grip clamps. Each type has its own specific design and function.

How do F-clamps work?

F-clamps have a sliding bar that moves back and forth along a stationary jaw. The clamp is tightened by turning a screw, which applies pressure to the sliding bar and holds the material in place.

How do parallel clamps work?

Parallel clamps use two stationary jaws that move in parallel to apply pressure to the material. They are typically used for larger projects and provide a more even and consistent clamping force.

How do pipe clamps work?

Pipe clamps use a stationary jaw and a sliding jaw that is attached to a length of pipe. The clamp is tightened by turning a screw that applies pressure to the pipe, which in turn applies pressure to the material being clamped.

How do quick-grip clamps work?

Quick-grip clamps have a sliding jaw that is tightened by squeezing a trigger or handle. They are designed for quick and easy clamping, but may not provide as much clamping force as other types of bar clamps.

How do I choose the right bar clamp for my project?

The type of bar clamp you choose will depend on the size and shape of the material you are working with, as well as the level of clamping force required. Consider factors such as the length of the clamp, the throat depth, and the maximum clamping pressure when selecting a bar clamp for your project.