Can I Use Any Drill Bit in a Drill Press? Here’s What You Need to Know.

When it comes to drilling, using the right accessories is essential. While drill bits may look the same, they come in different sizes, shapes, and materials, and each one has a specific purpose. But what happens when you have a drill press and a variety of drill bits? Can you use any drill bit in a drill press? The short answer is yes, but it depends on the specific drill bits and the type of drill press you have.

Let’s dive deeper into this question and explore some tips on how to choose the right drill bits for your drill press to achieve the best results.

Drill Press vs. Handheld Drill

If you’re a DIY enthusiast or a professional carpenter, you may have wondered whether you can use any drill bit in a drill press. The answer is yes, you can use any drill bit in a drill press, as long as the shank size matches the chuck size. However, the question you should ask yourself is whether it’s the best option for your particular project.

A drill press is designed for precision drilling, making it ideal for tasks that require accuracy and consistency. On the other hand, a handheld drill offers greater mobility and versatility, making it better suited for tasks that involve drilling in tight spaces or at different angles. Ultimately, it comes down to your personal preference and the specific needs of your project.

What is a drill press?

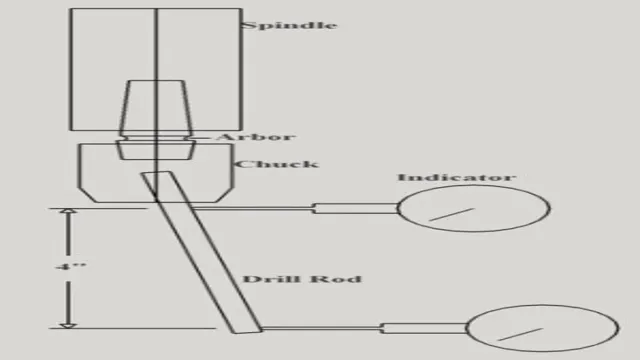

A drill press is a versatile tool that makes precise holes through various materials such as wood, metal, and plastic. It’s a powerful machine that consists of a base, column, spindle, and drill head. Many people wonder how a drill press differs from a handheld drill.

Simply put, while a handheld drill requires the user to hold and manipulate the drill to create a hole, a drill press is stationary and holds the material being drilled in place, making it easier to achieve more precise and accurate holes. The drill press can also create holes at different angles and depths, making it a go-to tool in workshops and manufacturing plants. Unlike handheld drills, which can cause fatigue with prolonged use, the drill press is designed to be ergonomically friendly, allowing for extended use with minimal discomfort.

So, if you want to achieve precise and consistent holes every time, then a drill press may be the tool for you.

How does a drill press differ from a handheld drill?

When it comes to drilling, two types of tools come to mind; the handheld drill and the drill press. The major difference between these two tools is the way they are used. A drill press is a stationary tool that is bolted down while a handheld drill is portable and can be carried around.

The drill press is much more precise than a handheld drill thanks to its ability to maintain a consistent angle and depth while drilling. The handheld drill, on the other hand, provides greater flexibility and mobility. It can access hard-to-reach areas that a drill press cannot and is ideal for smaller, less complicated tasks.

While both tools are excellent for specific uses, if precision and accuracy are what you’re after, the drill press is undoubtedly the better choice. Its stable base, powerful motor, and adjustable speed make it perfect for heavy-duty work. So if you’re working on a project that requires precision drilling, a drill press is perhaps the most recommended option.

Types of Drill Bits

When it comes to using a drill press, you may wonder if you can use any drill bit in it. The simple answer is that you can use most drill bits in a drill press, but it’s important to choose the right type of drill bit for the material you’re working with. For example, if you’re drilling through metal, you’ll want to use a high-speed steel or cobalt drill bit.

On the other hand, for wood or plastic, you can use a standard high-speed steel bit or a specialty bit like a spade or forstner bit. It’s also important to make sure the drill bit you’re using is the appropriate size for the job at hand. Ultimately, choosing the right drill bit for your drill press will help you achieve the desired results and ensure a safe and efficient drilling experience.

What are the different types of drill bits?

Drilling is a task that requires the right tools to ensure efficiency and accuracy. One essential tool in drilling is the drill bit. Drill bits come in different types, with each one suited for a specific material and drill type.

One of the most common types is the twist bit, which is ideal for drilling through wood, plastic, and light metals. For drilling through tougher materials like concrete, masonry, and ceramics, masonry bits are the best choice. Meanwhile, spade bits are perfect for creating large holes in wood.

For metal drilling applications, metal drill bits, also known as high-speed bits, are used. Auger bits are used to bore deep holes into wood. For glass, tile and granite drilling, diamond drilling bits are the ideal choice.

Lastly, step drill bits are used for drilling holes with varying diameters. Choosing the right type of drill bit can go a long way in ensuring the success of any drilling project.

Which drill bits are compatible with a drill press?

When it comes to using a drill press, it’s important to know which types of drill bits are compatible. The most common types of drill bits that can be used in a drill press are twist drill bits, spade bits, Forstner bits, and hole saws. Twist drill bits are the most common and can be used for a variety of materials, including wood, metal, and plastics.

Spade bits are great for drilling large holes in wood, and Forstner bits are ideal for creating flat-bottomed holes in wood. Hole saws are great for cutting large holes in metal and wood. It’s essential to use the correct drill bit for the material you’re working with to ensure the best results.

Always ensure that the drill bit is securely fastened in the drill press chuck before use. By using the right drill bits and following the proper safety procedures, you can create precise and consistent holes with a drill press.

Can you use specialty drill bits, such as masonry or glass bits, in a drill press?

When it comes to using a drill press, it’s important to consider the type of drill bits you’re using. There are a variety of drill bits available for specific materials, such as masonry bits for concrete and glass bits for, well, glass. But can you use these specialty bits in a drill press? The short answer is yes.

A drill press is designed with enough power and stability to handle the tougher jobs that specialty bits require. However, it’s essential to make sure that you’re using bits specifically designed for use in a drill press, as regular bits may not fit securely in the chuck or may not be able to withstand the force generated by the press. So, if you’re looking to tackle a tough job with a masonry or glass bit, go ahead and use your drill press – just be sure to use the right type of bit for the job.

Considerations When Using a Drill Press

When it comes to using a drill press, it is essential to consider the compatibility of the drill bits you plan to use. While it may be tempting to use any drill bit you have lying around, not all drill bits are created equal, and some may actually cause damage to your drill press. It is crucial to use drill bits specifically designed for use with a drill press, as they have certain characteristics that make them more suitable for this type of machine.

Additionally, using the wrong type of drill bit can cause dangerous kickbacks or cause the bit to break, potentially injuring you or damaging your equipment. So, while it may seem like a small detail, taking the time to ensure that you are using the right drill bits for your drill press can make a significant difference in the safety and effectiveness of your work.

What safety precautions should be taken when using a drill press?

When using a drill press, it’s essential to take safety precautions seriously to avoid accidents that could result in serious injury. Firstly, make sure the drill press is switched off and unplugged before making adjustments or changing drill bits. When drilling, always wear eye protection to prevent debris from flying into your eyes.

Additionally, avoid loose clothing or jewelry that could get caught in the moving parts. Always secure the workpiece and use a clamp whenever possible to prevent it from spinning or moving. It’s also crucial to adjust the speed of the drill press to match the type of material you are drilling into.

Using the wrong RPM setting can cause the drill bit to overheat and break. By following these considerations, you can ensure safe and productive use of your drill press.

What materials can be drilled using a drill press?

When it comes to drilling materials using a drill press, there are several factors to consider. Firstly, the material you intend to drill needs to be suitable for the type of drill bit you are using. For example, softer materials such as wood and plastic require lower speed and force while harder materials such as metal and concrete require higher speed and force to avoid damage to the bit.

Additionally, the type of bit you use will affect the material you can drill. For example, a diamond bit can drill through hard materials like glass and ceramics with ease, while a spade bit is better suited for wood. It’s important to choose the appropriate bit and drilling speed to avoid breaking the bit or damaging the material.

With the right bit and drilling conditions, a drill press can be used to drill through a variety of materials including wood, metal, plastics, glass, and ceramics.

Conclusion

In conclusion, using any drill bit in a drill press is like trying to fit a square peg into a round hole. It may seem like a good idea at first, but ultimately it will lead to frustration and potentially disastrous results. Instead, invest in quality drill bits that are specifically designed for use with a drill press for efficient and successful drilling every time.

Remember, sometimes it’s worth investing in the right tool for the job.”

FAQs

What is the difference between a drill bit and a drill press?

A drill bit is a cutting tool used to create holes in a material, while a drill press is a machine used to drill holes with precision and accuracy.

Can I use any drill bit in a drill press?

Generally, yes. However, it is important to make sure that the drill bit you are using is compatible with the drill press. The shank size and type of drill bit should match the chuck of the drill press.

What is the depth capacity of a drill press?

The depth capacity of a drill press depends on the model and make. Most drill presses have a depth capacity of 3 to 4 inches.

How do I align my workpiece on the drill press table?

To align your workpiece on the drill press table, use a center punch to make a mark on the material. Then, use a square to line up the mark with the table’s edge.

How do I change the speed on a drill press?

To change the speed on a drill press, adjust the drive belt or pulley system. Most drill presses have a chart that indicates which belt or pulley position to use for specific drill bit sizes and materials.

How do I maintain my drill press?

To maintain your drill press, keep the table and mechanism clean and lubricated. Check the chuck and belts for wear and replace them as needed.

What safety precautions should I follow when using a drill press?

Wear eye and ear protection, tie back long hair, remove loose clothing and jewelry, and avoid loose clothing. Make sure the workpiece is securely clamped to the table and turn off the machine before making any adjustments.