Can You Use a Milling Table with a Drill Press for Accurate and Efficient Drilling?

Have you ever considered using a milling table with your drill press? If not, you might be missing out on some major advantages. A milling table is a flat surface that can be attached to your drill press, allowing you to mill or shape materials with precision and accuracy. This tool is commonly used by metalworkers and woodworkers, but it can also be helpful for DIY enthusiasts who want to take their projects to the next level.

By using a milling table with your drill press, you can create intricate designs, drill holes at exact angles, and even make repetitive cuts with ease. This tool is especially useful for those who work with small or delicate pieces, as it provides a stable and precise surface to work on. Additionally, a milling table can save you time and money by allowing you to do multiple tasks in one machine, instead of having to switch between a drill press and a dedicated milling machine.

Overall, a milling table is a versatile and valuable tool that can help you achieve professional results in your work. Whether you are a seasoned craftsman or a DIY enthusiast, using a milling table with your drill press is a great way to expand your capabilities and take your projects to the next level. So why not give it a try and see what you can create?

Introduction

If you’re someone who loves to work on DIY projects, you may have wondered whether you can use a milling table with a drill press. The answer is yes, you can use a milling table with a drill press to get more versatility and accuracy in your work. A milling table is a flat surface that can move in different directions for cutting materials with precision and control.

On the other hand, a drill press is a machine designed to drill holes in materials at various angles and depths. By combining these two tools, you can create a milling machine that can perform a variety of tasks. However, keep in mind that a drill press has limitations in terms of power, speed, and stability compared to a milling machine.

Therefore, while you can use a milling table with a drill press, you will not achieve the same level of accuracy and durability as with a dedicated milling machine.

Explanation of a Milling Table and Drill Press

A milling table and drill press are two essential tools that are often found in a machine shop or garage. These tools help to drill precise holes in a variety of materials and can even be used for cutting metal. A milling table is essentially a table that can be adjusted to different angles and heights, allowing the user to drill at any desired angle.

The table is also equipped with T-slots, which allow for the attachment of clamps or vises to hold the workpiece in place during drilling. A drill press, on the other hand, is a machine that is used to drill holes with precision and accuracy. It has a spindle that rotates at high speed, and the user can adjust the speed of the spindle depending on the material being drilled.

The drill press also has a table that can be adjusted up and down to accommodate the workpiece. Whether you are a seasoned professional or a DIY enthusiast, a milling table and drill press are essential tools for any serious workshop or garage. By ensuring that you have the right tools and equipment at your disposal, you can easily tackle any project with ease and confidence.

Pros and Cons of Using a Milling Table with a Drill Press

Yes, you can use a milling table with a drill press, but there are pros and cons to consider. A milling table can increase the versatility of your drill press, allowing you to perform tasks like milling, drilling, and slotting. However, it may not be as accurate as a dedicated milling machine, which can limit the precision of your work.

Additionally, a milling table can add weight to your setup, which may cause strain on the drill press’s motor and bearings. Overall, if you’re looking to do light milling work and want to make the most of your tool investment, a milling table can be a useful addition to your drill press. But if precision is paramount, it may be worth the investment in a dedicated milling machine.

So, while using a milling table with a drill press is possible, it’s essential to weigh the pros and cons before deciding whether it’s the right choice for your needs.

Advantages to Using a Milling Table with a Drill Press

Using a milling table with a drill press can have many advantages, but it also comes with a few drawbacks. One of the significant benefits of using a milling table is that it allows for more precise drilling and milling operations. The table’s surface is flat, providing a stable platform for the workpiece, reducing the chance of errors.

Additionally, the table can be adjusted to any angle, allowing for more versatility in operations. Another advantage is that the milling table greatly expands the drill press’s capabilities, making it more versatile and useful for a variety of tasks. However, there are some cons to consider.

A milling table can be expensive and might not be worth the investment. Moreover, due to the drill press’s limited power and speed, milling operations with the table might be slow and time-consuming. Therefore, it is essential to weigh the benefits and drawbacks before deciding whether a milling table is the best option for your specific needs and budget.

Disadvantages to Using a Milling Table with a Drill Press

One of the primary disadvantages of using a milling table with a drill press is that it can be dangerous. A milling table is meant for milling machines, which are made for precise cutting and shaping of metal. Using a drill press for milling, even with a table, can result in broken bits, damaged equipment, and injuries.

Another drawback is that drill presses have limited horsepower for milling, especially when it comes to larger or tougher metal pieces. Moreover, a drill press’s bearings are not designed to withstand the side-to-side forces of milling, meaning the machine can wear out more quickly. In conclusion, while a milling table can be beneficial for some drilling operations, it comes with several disadvantages, making it less ideal and often, unsafe.

It’s best to use the right tool for the job and avoid the temptation of repurposing machinery for tasks it’s not designed to handle.

Tips for Using a Milling Table with a Drill Press

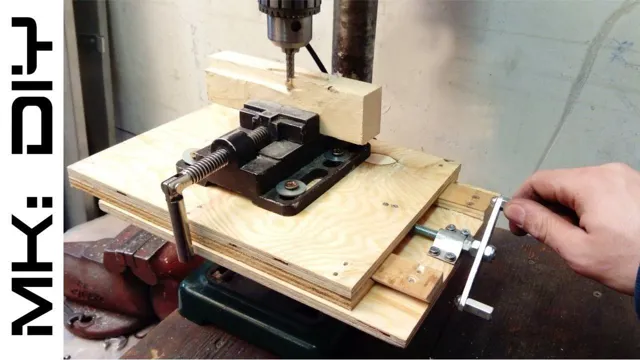

Yes, you can definitely use a milling table with a drill press. In fact, a milling table can make your drill press more versatile and allow you to perform tasks that might not be possible with just the drill press alone. The milling table provides a flat and stable surface for you to work on, allowing you to clamp down your workpiece securely.

This means you can accurately drill holes at specific angles and depths without worrying about the workpiece moving around. With a milling table, you can also easily perform tasks like edge drilling, slot cutting, and cross drilling. Though it’s important to note that while a milling table can expand the capabilities of your drill press, it cannot replicate the precision or features of a dedicated milling machine.

So, if you’re looking to perform more advanced milling tasks, you might want to invest in a proper milling machine instead.

Choosing the Right Milling Table and Drill Press

When it comes to using a milling table with a drill press, there are a few things to keep in mind to get the best results. First and foremost, it’s important to choose a milling table that is compatible with your drill press and can handle the weight and size of the materials you will be working with. The size of the table should also be considered, as it should be large enough to accommodate your workpiece without being too cumbersome.

Additionally, make sure to adjust the table height so that it is at the right level for your specific project. Another important tip is to properly secure your workpiece to the milling table using clamps or vices to prevent any accidents. By following these tips, you can ensure your milling table and drill press work together effectively to produce high-quality, precise cuts every time.

Aligning the Milling Table with the Drill Press

aligning the milling table with the drill press. Using a milling table with a drill press can be a great way to add accuracy and precision to your drilling projects. However, aligning the milling table with the drill press can be a bit tricky.

Here are some tips to help you get started. First, make sure that your drill press is level and stable. Next, attach the milling table to the drill press and check that it is level as well.

You may need to adjust the table’s height or angle if necessary. Once the milling table is attached and level, you can begin to align it with the drill press. Start by loosening the bolts that hold the milling table in place.

Then, use a dial indicator to check the alignment of the milling table with the drill press. Adjust the table as needed until it is perfectly aligned. Finally, tighten the bolts and double-check the alignment before use.

By following these tips, you can use a milling table with a drill press to achieve accurate and precise results in your drilling projects. So, don’t be afraid to give it a try and see the difference for yourself.

Cutting Techniques and Safety Precautions

If you’re looking for a way to make your drill press more versatile, consider investing in a milling table. This table attaches to your drill press and allows you to easily cut and mill materials like wood, metal, and plastic. However, it’s important to take certain safety precautions when using this tool.

Always wear eye and ear protection to prevent injury from flying debris and loud noises. You should also make sure the milling table is securely attached to the drill press to prevent any accidents. To avoid the risk of injury, it’s crucial to learn proper cutting techniques.

Make sure you’re using the appropriate cutting speed and depth for the material you’re working with, and feed the material into the milling table at a steady pace. With these tips in mind, you can use a milling table with your drill press safely and effectively.

Conclusion and Final Thoughts

In conclusion, using a milling table with a drill press is like trying to play rock and roll on a classical guitar – you might be able to make it work, but it’s not the most efficient or effective way to get the job done. While it may be tempting to cut corners and use equipment in ways they weren’t intended for, investing in the proper tools for each task will save you time, money, and headache in the long run. So, unless you’re ready to face the music and deal with the consequences, stick to using your milling table with a proper milling machine and let your drill press do what it does best – drill.

“

FAQs

What is a milling table and how is it used with a drill press?

A milling table is a platform with a smooth flat surface used to hold workpieces securely during drilling, cutting, or shaping. It can be attached to a drill press to provide more precise and accurate results.

Can any drill press be used with a milling table?

Not all drill presses are compatible with milling tables. The drill press must have a column that is sturdy enough to support the weight of the milling table and the workpiece. It should also have a mechanism that allows the table to be adjusted up and down or side to side.

What are the advantages of using a milling table with a drill press?

Using a milling table with a drill press allows you to cut and shape materials with more precision and accuracy. It also provides a stable base for the workpiece, reducing the risk of errors or accidents.

Can a milling table be used for other types of tools besides drill presses?

Yes, a milling table can be used with other types of tools like routers, saws, or grinders. However, it is important to ensure that the tool is compatible with the table and that the table is securely attached before use.

How do I choose the right milling table for my drill press?

When choosing a milling table, consider the size and weight of your drill press, as well as the size of your workpiece. Look for a table that is made of durable materials like cast iron or steel, and that has adjustable locking mechanisms for precise positioning.

What safety precautions should I take when using a milling table with a drill press?

Always wear eye and ear protection when using power tools. Ensure that the table and drill press are securely locked in place before use. Keep loose clothing and long hair away from moving parts, and never attempt to remove or adjust the workpiece while the tool is still running.

Can I use a milling table with a handheld drill?

No, a milling table is designed to be used with stationary tools like drill presses, which provide a stable base for the workpiece. Using a handheld drill with a milling table can be dangerous and result in inaccurate or uneven cuts.