Can You Use a Milling Machine as a Drill Press? Pros and Cons You Need to Know

Milling machines are versatile pieces of equipment that can be used for a variety of purposes, including drilling holes. If you don’t have access to a drill press, or if you need to make large or precise holes, a milling machine can be a great alternative. But how easy is it to use a milling machine as a drill press? In this blog post, we’ll explore the process of using a milling machine for drilling, the advantages of this approach, and some tips to make your work easier and safer.

So, grab a cup of coffee and let’s get drilling!

Understanding the Differences Between a Milling Machine and a Drill Press

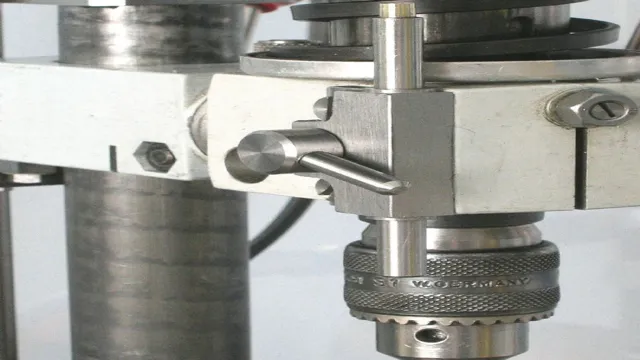

Many people wonder if it’s possible to use a milling machine as a drill press, given that they share a similar appearance. While both tools can be used to drill holes, there are significant differences between them. A milling machine is designed to remove material from a workpiece, while a drill press is designed to create holes by drilling straight down into a workpiece.

A milling machine has a cutter mounted on a spindle that can move in multiple directions, allowing for complex cuts and shapes. A drill press has a simple, vertical motion that only allows for straight, downward drilling. While it may be possible to use a milling machine as a drill press in limited situations, it is not recommended as it can be dangerous and lead to inaccurate holes.

It’s important to use the right tool for the job to ensure safety and precision.

Concept of a Milling Machine

A milling machine and a drill press may appear similar, but there are significant differences between the two. While a drill press is mainly used for drilling holes, a milling machine can be utilized for various applications like cutting, shaping, and drilling. In a milling machine, the cutting tool rotates while the workpiece is held in place, enabling the operator to create precise cuts and shapes.

On the other hand, the drill press uses a spindle to hold the drill bit, making it ideal for creating holes. In short, a drill press is a simple tool that’s great for drilling holes, but if you require more versatility and accuracy, then a milling machine is what you need. So, consider your needs and application before choosing which tool to use.

Concept of a Drill Press

A drill press and a milling machine are two common tools found in machine shops and metalworking facilities. Although they share some similarities, they perform different functions and come with distinct features. A drill press is primarily used for drilling holes into metal, wood, and plastic materials.

It operates by clamping the workpiece onto a table and lowering a drill bit onto the surface to create the desired hole. It is a versatile tool that can handle a range of tasks, from small hobby projects to larger industrial work. A milling machine, on the other hand, is used for cutting and shaping metal and other hard materials.

It uses a rotating cutting tool to remove material from the workpiece and create complex shapes and designs. Unlike drill presses, milling machines have a more specific range of applications and are often used in manufacturing and production settings. They can be highly precise and produce consistent results.

While both tools are useful in their own right, the key difference lies in their capabilities. A drill press can only produce round holes, while milling machines can create a wide range of shapes and cuts. Drill presses are also generally simpler and less expensive, making them a better choice for those on a budget.

Ultimately, the choice between a drill press and a milling machine comes down to the specific needs of the project and the skill level of the operator.

Comparison of a Milling Machine and a Drill Press

When it comes to metalworking tools, a milling machine and a drill press are two of the most commonly used machines. The primary difference between the two is that a milling machine is capable of moving the material being worked on in multiple directions, while a drill press can only move up and down. This means that a milling machine can perform more complex cuts and shapes, while a drill press is best suited for simple drilling tasks.

Another key difference between the two is the types of bits they use. A drill press uses a drill bit, while a milling machine uses a variety of cutting tools, such as end mills and ball mills. Ultimately, the choice between a milling machine and a drill press depends on the type of work you need to do.

If you need to perform complex cuts and shapes, a milling machine is the way to go. If your work is mainly focused on drilling, a drill press is the better option.

The Advantages and Disadvantages of Using a Milling Machine as a Drill Press

When it comes to drilling precision holes on materials like metal and wood, many people wonder if they can use a milling machine as a drill press. While it’s technically possible to use a milling machine for drilling, there are both advantages and disadvantages to doing so. The main advantage is that a milling machine can drill holes more accurately and with less vibration than a drill press.

On the other hand, milling machines are bulkier and less portable than drill presses, making them less suitable for small and quick drilling jobs. Additionally, milling machines are usually more expensive than drill presses, so they may not be cost-effective if drilling is your primary task. In summary, using a milling machine as a drill press can be a good choice for precision drilling tasks, but it’s important to weigh the pros and cons before making a final decision.

Advantages of Using a Milling Machine as a Drill Press

One of the advantages of using a milling machine as a drill press is precision. Milling machines are equipped with feature-rich controls that allow precision drilling at a higher level than drill presses. The machine’s table can be adjusted to make a perfect right angle that helps you to drill incredibly accurate holes.

Compared to a drill press, a milling machine also offers a more streamlined drilling process, thanks to its ability to hold and work on multiple drill bits at a time. The milling machine saves a lot of time and effort by reducing the need to stop and change bit sizes constantly. The hydraulic feed allows for an easy, automated way to achieve depth control and reduce operator error.

Disadvantages of using milling machines exclusively for drilling include the high cost of machine setup and the requirement for larger workpieces. While the milling machine can serve the purpose of a drill press, it comes with added cost. Milled holes are also typically more expensive than a drilled hole.

Nevertheless, it is worth the investment if you require precise and efficient drilling in your manufacturing or individual projects.

Disadvantages of Using a Milling Machine as a Drill Press

Using a milling machine as a drill press can be a convenient option, but it also comes with some disadvantages. One of the drawbacks is the cost. Milling machines are more expensive than drill presses, so if you’re looking for a cheaper option, a drill press might be a better choice.

Additionally, milling machines require more skill and training to operate effectively. They have a steeper learning curve and are not as user-friendly as a drill press. Another disadvantage is the size and weight of the machine.

Milling machines are often larger and heavier than drill presses, so they can be difficult to move around and store. Finally, milling machines can be more cumbersome when it comes to changing tools. Drill presses have simple, quickly interchangeable tooling systems, whereas milling machines have more complex systems that can be time-consuming to set up.

Overall, while a milling machine may be a useful option for some projects, drill presses are still the more practical choice for simple drilling tasks.

How to Safely Use a Milling Machine as a Drill Press

There’s no doubt that a milling machine is an incredibly versatile piece of equipment that can be used to perform a wide range of machining tasks. But can you use a milling machine as a drill press? The answer is yes, but there are a few things you need to keep in mind to ensure you do it safely. First, make sure you have the right tools for the job.

This means using a properly-sized drill bit, as well as a collet or chuck to hold it in place. Second, be sure to secure the workpiece to the milling table with clamps or other holding devices to prevent it from shifting during drilling. Finally, always wear appropriate personal protective equipment, such as safety glasses and earplugs, to protect yourself from flying chips and loud noises.

Follow these guidelines, and you can use your milling machine as a drill press with confidence.

Steps to Follow for Safe Usage

When using a milling machine as a drill press, safety should always be a top priority. Start by ensuring that the machine is properly set up and that all safety guards are in place. Next, select the appropriate drill bit for the material you’ll be drilling, and adjust the machine’s speed accordingly.

Be sure to properly secure the workpiece in place, using clamps or vises if necessary. When drilling, take care to avoid applying too much pressure to the bit, as this can cause it to break. And always be aware of your surroundings, keeping your hands and clothing away from moving parts.

By following these steps, you can ensure safe and effective use of your milling machine as a drill press. Remember, safety first!

Safety Precautions to Take Before Starting Work

When using a milling machine as a drill press, there are some crucial safety precautions you should take before starting work. First, make sure you are wearing the appropriate personal protective equipment, such as safety glasses and work gloves. Next, ensure that the machine is in good working condition and that all guards and safety devices are in place and functioning correctly.

Additionally, it’s essential to know the limitations of the machine and only use it for its intended purposes. When using a milling machine as a drill press, never exceed the recommended drilling capacity and always use the appropriate drill bits for the job. Remember to secure the workpiece firmly using clamps or fixtures and always keep your hands away from moving parts.

Following these safety precautions can help ensure a successful and safe milling machine experience. Keywords: milling machine, drill press, safety precautions, personal protective equipment, workpiece.

Conclusion

In conclusion, while it may be possible to use a milling machine as a drill press, it is ultimately a bit like using a hammer to screw in a nail – technically feasible, but at the end of the day, not the best tool for the job. Sure, both machines may involve rotating a cutting tool, but the precision and capabilities of a drill press far surpass those of a milling machine when it comes to drilling operations. So if you’re in the market for a tool to make those holes, don’t get wrapped up in the idea of multi-functionality – invest in a proper drill press and save yourself from the headache (and potential safety risks) of trying to make a milling machine do something it’s not designed for.

“

FAQs

What is a milling machine?

A milling machine is a tool that uses rotary cutters to remove material from a workpiece.

What is a drill press?

A drill press is a tool used for making holes in a workpiece by rotating a drill bit.

What is the difference between a milling machine and a drill press?

While both machines can be used to make holes in a workpiece, a milling machine is also capable of removing material in other ways, such as cutting slots, grooves, and shapes.

Can you use a milling machine as a drill press?

While a milling machine can technically be used to drill holes, it is not typically the best tool for the job. Drill presses are generally faster, more accurate, and easier to set up for drilling.

What are some advantages of using a milling machine over a drill press?

Milling machines can be used for a variety of other tasks beyond drilling holes, such as cutting threads, milling gears, and making complex shapes. They are also generally more precise and accurate than a drill press.

Can a drill press be used for milling?

While a drill press can technically be used for milling, it is not designed for this task and may not be able to produce the same level of precision and accuracy as a milling machine.

What are some safety considerations when using a milling machine or drill press?

Always wear eye protection and gloves when operating these machines. Ensure that the workpiece is properly secured and that the cutting tool is in good condition and properly aligned. Follow all manufacturer’s instructions and warnings.