Can You Use a Heat Gun to Dry Joint Compound? A Comprehensive Guide for Quicker Results

If you’ve ever undertaken a DIY project that involves drywall or joint compound, you likely know the frustration of waiting for it to dry. It can take hours, sometimes even days, to dry completely, leaving you with a project that’s on hold until it’s ready. So, you might be wondering if there’s a faster way to dry joint compound.

Can you use a heat gun to speed up the drying process? In short, the answer is yes, but with a few important caveats. Using a heat gun can certainly accelerate the drying time of joint compound, but it’s important to use caution and follow some basic guidelines to avoid causing damage to your project or even creating a fire hazard. Let’s take a closer look at what you need to know.

Understanding Joint Compound Drying Process

If you’re wondering whether a heat gun can be used to speed up the joint compound drying process, the answer is yes, but with caution. While a heat gun can be an effective tool for drying joint compound, it can also cause cracks or bubbles if used improperly. It’s essential to keep the heat gun moving constantly, so as not to heat one area too much and cause damage.

Also, it’s crucial to hold the heat gun at a safe distance, at least six to eight inches away from the surface to be dried. Before using a heat gun, make sure the joint compound layer is smooth and dry to the touch, as heating wet compound can cause it to bubble or boil. In summary, using a heat gun can speed up the drying process, but it requires caution, precision, and experience to avoid causing damage to the compound.

Factors Affecting Joint Compound Drying Time

Joint compound drying time can be affected by numerous factors. One of these is humidity, as higher levels of moisture in the air can slow down the drying process. Temperature is also key, as cooler temperatures will cause joint compound to take longer to dry than warmer ones.

The thickness of the compound layer applied also matters, as thicker layers will take longer to dry than thinner ones. Other factors include the type of joint compound used and the surface being applied to. Understanding the joint compound drying process is important to ensure a successful outcome.

It’s crucial to follow manufacturer guidelines carefully, and to factor in environmental conditions and the size of the application area when estimating drying times. Ultimately, patience is key when it comes to joint compound drying time – rushing the process can result in a less-than-perfect final product. So, take the time to let the joint compound dry completely and enjoy the satisfaction of a job well done.

Why You Shouldn’t Rely on Heat Guns for Drying Joint Compound

Joint compound Heat guns When it comes to renovating or remodeling a room, joint compound is a necessary material. It helps to fill in any gaps or cracks in walls or ceilings, giving a smooth surface for painting or wallpaper. The drying process for joint compound is crucial to ensure a flawless finish, and many people turn to heat guns to speed up the process.

However, relying on heat guns can cause more harm than good. While the heat may dry the surface, it can also create bubbles or cracks in the compound below the surface that won’t show up until after painting. It is best to let the compound dry naturally or use a fan to circulate air in the room for faster drying.

Joint compound drying time can vary depending on humidity and temperature, so it’s essential to be patient and allow at least 24 hours for it to dry completely. It may take longer to dry if the layer is thicker, so it’s best to apply thinner layers and build up if necessary. Remember to take your time, and resist using heat guns for the sake of saving time.

Your finished product will be worth it.

Alternatives to Heat Guns for Drying Joint Compound

Many people wonder if they can use a heat gun to dry joint compound. While it may seem like a quick and easy solution, there are actually several reasons why this isn’t the best idea. For starters, heat guns can cause the joint compound to dry too quickly, which can result in cracking and other imperfections.

Additionally, the heat can cause the joint compound to dry unevenly, leading to areas that are over-dried and others that are still wet. So what are some better alternatives? One great option is to simply allow the joint compound to air dry. This may take longer, but it’s a much safer and more effective approach.

Another option is to use a dehumidifier to help speed up the drying process. By removing excess moisture from the air, a dehumidifier can help the joint compound dry more evenly and effectively. Overall, while a heat gun may seem like a tempting shortcut, there are safer and more effective ways to dry joint compound without risking damage or imperfections.

Using Air Circulation and Fans to Dry Joint Compound

If you’re looking for alternatives to heat guns for drying joint compound, consider using air circulation and fans to speed up the process. One of the best things about this method is that it is a much safer alternative to heat guns, which can be a fire hazard if not used properly. By using air circulation and fans, you can dry the joint compound quickly without risking any damage to your materials or your safety.

Plus, this method is more energy efficient than using a heat gun, as it relies solely on air movement to dry the compound. Just make sure to keep the air circulating in the room and move the fan around periodically to ensure even drying. With this method, you’ll have perfectly dry joint compound in no time.

Using Dehumidifiers to Dry Joint Compound

If you’ve ever tried to dry joint compound on a wall or ceiling, you may have heard of using a heat gun to speed up the process. However, heat guns can be dangerous if not used properly and can cause damage to the surrounding area. A safer and more effective alternative to using a heat gun is to use a dehumidifier.

Dehumidifiers work by pulling moisture out of the air, which can help dry the joint compound faster. Simply set up the dehumidifier in the room where the joint compound is drying and let it run. This method may take longer than using a heat gun, but it is much safer and can be more effective in the long run.

Plus, you won’t have to worry about damaging the wall or ceiling with high heat. So next time you need to dry joint compound, consider using a dehumidifier instead of a heat gun. Your walls and safety will thank you.

Using Natural Evaporation to Dry Joint Compound

When it comes to finishing up a drywall job, drying joint compound can be a time-consuming task. While many people turn to heat guns to expedite the process, there are alternative methods that can be just as effective and less damaging to the materials. One such method is using natural evaporation to dry joint compound.

This process involves opening windows and doors in the room, turning on fans to circulate air, and letting the moisture in the compound naturally evaporate over time. Not only does this avoid the potential damage that heat guns can cause, it also saves money on energy bills. So next time you’re finishing up a drywall project, consider using natural evaporation to dry your joint compound instead of relying on heat guns.

Your wallet (and drywall) will thank you!

Final Words of Caution

While it may be tempting to speed up the drying process of joint compound with a heat gun, it is generally not recommended. While a heat gun can certainly help the compound dry faster, it can also cause a whole host of issues if not used properly. For one, it can cause the compound to dry too quickly, resulting in cracks and other imperfections.

Additionally, the heat can cause the compound to bubble and blister, ruining the finish. Finally, a heat gun can be dangerous if used improperly, potentially causing fires or burns. In short, while a heat gun can be a useful tool in the right circumstances, it is generally best to let joint compound dry naturally, typically overnight or for at least several hours.

Safety Precautions When Drying Joint Compound

When it comes to drying joint compound, there are a few safety precautions that need to be taken to ensure a safe and successful project. First and foremost, make sure the room is well-ventilated and that you’re wearing a respirator mask to protect yourself from inhaling any dust or particles. Additionally, keep the area free of any flammable materials or substances, and avoid smoking or using any open flames in the room during the drying process.

It’s also critically important to follow the manufacturer’s instructions for drying times and product application, as this will help you achieve the best results while minimizing any risks associated with the process. Finally, if you do experience any adverse health effects while working with joint compound, such as dizziness, fatigue, or respiratory issues, stop working immediately and seek out medical attention right away. By taking these safety precautions and following best practices for drying joint compound, you can achieve great results while keeping yourself and your workspace safe.

When to Call in a Professional

As much as we would love to be able to handle all of our home improvement projects on our own, there are definitely some times when it’s necessary to call in a professional. Whether it’s because we lack the necessary skills or equipment, or just don’t have the time or patience to handle the task ourselves, there’s no shame in admitting that we need help. However, it’s important to remember that not all professionals are created equal.

When hiring someone to work on your home, make sure you do your research and choose someone who is experienced, licensed, and insured. You don’t want to end up with a shoddy job just because you hired the first person you found. Additionally, don’t be afraid to ask questions or voice concerns.

A good professional will be happy to address any issues you may have and will work with you to ensure that you are satisfied with their work. In the end, it’s better to spend a little extra money upfront to hire a qualified professional than to end up with a costly disaster on your hands.

Conclusion

In conclusion, while using a heat gun to dry joint compound may seem like a quick and easy solution, it’s important to remember that haste makes waste. Applying too much heat can cause the compound to dry too quickly, leading to cracking and other structural issues. So while you technically can use a heat gun to dry joint compound, it’s always best to exercise caution and allow the compound to dry naturally for the best possible finish.

Don’t let impatience sabotage your project – take your time and let the compound do its thing!”

FAQs

How does using a heat gun to dry joint compound compare to air drying?

Using a heat gun can speed up the drying process of joint compound, but it can also cause cracking and shrinkage if not used carefully. Air drying is slower but may result in a smoother and more even finish.

What temperature should a heat gun be set to when drying joint compound?

It depends on the type of joint compound and the manufacturer’s recommendations. Generally, a temperature of 120-140 degrees Fahrenheit is considered safe for drying joint compound with a heat gun.

Can a heat gun be used to dry joint compound in humid conditions?

It is not recommended to use a heat gun in high humidity because it can cause the joint compound to dry unevenly or not at all. In humid conditions, it is better to allow the joint compound to air dry or use a dehumidifier in the room.

What safety precautions should be taken when using a heat gun to dry joint compound?

Always wear safety goggles and gloves, and make sure the area is well ventilated to avoid inhaling fumes. Keep the heat gun moving at all times and never let it stay in one spot for too long to prevent scorching or burning the joint compound.

Can a heat gun be used to dry joint compound on vertical surfaces?

Yes, a heat gun can be used on vertical surfaces, but extra care should be taken to avoid drips or sagging. It may be helpful to use a smaller heat gun with a more directed nozzle to control the airflow.

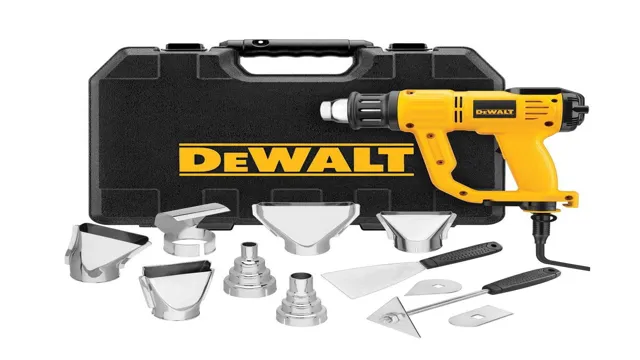

What is the best type of heat gun to use for drying joint compound?

A variable temperature heat gun is best because it allows for more control over the heat output. It is also helpful to have a heat gun with multiple nozzle attachments for different types of surfaces.

Is it possible to over-dry joint compound with a heat gun?

Yes, over-drying joint compound with a heat gun can cause it to become brittle and crack. It is important to follow the manufacturer’s recommendations and avoid using the heat gun for too long in one area.